Cerberus

Cerberus the aardvark, not the hell-hound!!

- Local time

- 3:29 PM

- User ID

- 11523

- Joined

- Jan 20, 2020

- Messages

- 292

- Reaction score

- 121

- Location

- Florida (tampa area)

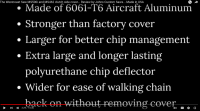

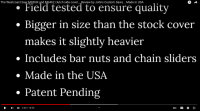

So I was drawn to the XL Stihl 660 clutch-cover, figured "Better chip-dispersal is good because sometimes I do palms, they clog so fast!" (clutch-pack of palm fibres led to the only fail of my chinese 660, a popped clutch-spring)

TL;DR-- if you can choose clutch-covers, wouldn't you want size or volume in the "rear" especially "rear-lower" portion of the clutch-cover? For instance, XL 660 covers simply flare-outwards (whereas an OEM cover, at that spot, has a flared-bottom that tapers inwards & outwards, actually just removing the inward-flare gives you ~10% more lateral area for chips to escape), am I wrong in thinking "more space" = better, here? Or is there a spot you want a choke/tight spot, maybe to prevent chips going up&over the clutch's top?

~~~~~~~~~~~~~~~~

Sadly, after seeing a video on the XL's, and inspecting the regular OEM, it seems neither is optimized for chip dispersal, I mean the "rubber chute" on the left side/bottom of the XL is so wide it literally restricts space worse than OEM:

https://cdn.shopify.com/s/files/1/0312/7533/products/066WESTCOASTCOVER-4_480x480.jpg?v=1642186470

The WCS's (sexy) billet cover is the same form/mold...

Is there some kind of reasoning behind the XL "boot", maybe it is good to restrict space in some areas of the clutch-cover? Kinda like preventing the chips from going up&over the sprocket, having a "choke-point" that catches them around the 9pm-->11pm point from the clutch's centerpoint, to cause "spitback" of chips, out&down, from there?

Cannot help thinking the best is to simply use an OEM, remove the rubber chute thing entirely for the extra space, and even take an angle grinder (w/ flap-disk) to that inward-tapered bottom of the cover, expanding the total "width" by over 10% (width of powerhead to clutch-cover's inside facing)

Can't think of any reason that more space "beneath 9pm", at least, would be optimal -- but wanted to ask here before fiberglassing my own or otherwise altering in a way that turns-out to be improper! Thanks

TL;DR-- if you can choose clutch-covers, wouldn't you want size or volume in the "rear" especially "rear-lower" portion of the clutch-cover? For instance, XL 660 covers simply flare-outwards (whereas an OEM cover, at that spot, has a flared-bottom that tapers inwards & outwards, actually just removing the inward-flare gives you ~10% more lateral area for chips to escape), am I wrong in thinking "more space" = better, here? Or is there a spot you want a choke/tight spot, maybe to prevent chips going up&over the clutch's top?

~~~~~~~~~~~~~~~~

Sadly, after seeing a video on the XL's, and inspecting the regular OEM, it seems neither is optimized for chip dispersal, I mean the "rubber chute" on the left side/bottom of the XL is so wide it literally restricts space worse than OEM:

https://cdn.shopify.com/s/files/1/0312/7533/products/066WESTCOASTCOVER-4_480x480.jpg?v=1642186470

The WCS's (sexy) billet cover is the same form/mold...

Is there some kind of reasoning behind the XL "boot", maybe it is good to restrict space in some areas of the clutch-cover? Kinda like preventing the chips from going up&over the sprocket, having a "choke-point" that catches them around the 9pm-->11pm point from the clutch's centerpoint, to cause "spitback" of chips, out&down, from there?

Cannot help thinking the best is to simply use an OEM, remove the rubber chute thing entirely for the extra space, and even take an angle grinder (w/ flap-disk) to that inward-tapered bottom of the cover, expanding the total "width" by over 10% (width of powerhead to clutch-cover's inside facing)

Can't think of any reason that more space "beneath 9pm", at least, would be optimal -- but wanted to ask here before fiberglassing my own or otherwise altering in a way that turns-out to be improper! Thanks