- Local time

- 9:24 AM

- User ID

- 319

- Joined

- Dec 29, 2015

- Messages

- 9,499

- Reaction score

- 62,181

- Location

- Strong Island NY

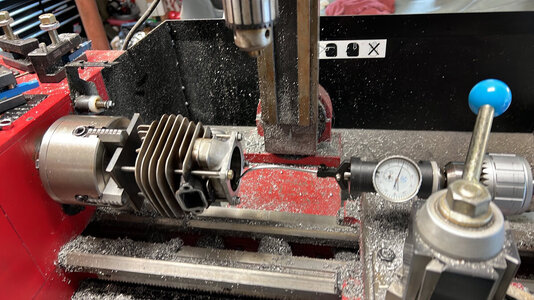

Odd issue with a Mahle 034 Super jug.

A first for me. All was going well until my final band cut. I came back into cylinder was like I always do by around .002 and heard a ripping noise. I was already at .037 out of the band and was going for the final .003 cut which I like to do with autofeed.

The plating ripped away from the jug. It’s probably fine to use, as it still sits above the top ring, but this jug is going across the pond and I don’t want any issues.

I’ve done hundreds of jugs the same way at this point, and this is a first. I found another jug in my stash and did it the same way without an issue. I’m trying to figure out if it was a manufacturing defect in the jug, or just one of those things.

Here is the problem child.

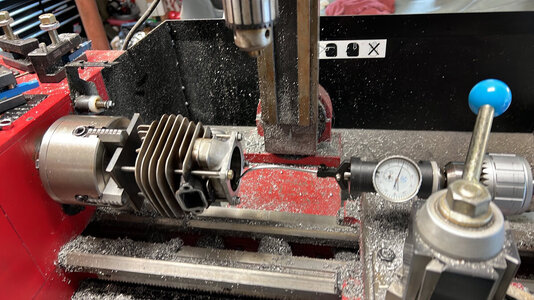

A first for me. All was going well until my final band cut. I came back into cylinder was like I always do by around .002 and heard a ripping noise. I was already at .037 out of the band and was going for the final .003 cut which I like to do with autofeed.

The plating ripped away from the jug. It’s probably fine to use, as it still sits above the top ring, but this jug is going across the pond and I don’t want any issues.

I’ve done hundreds of jugs the same way at this point, and this is a first. I found another jug in my stash and did it the same way without an issue. I’m trying to figure out if it was a manufacturing defect in the jug, or just one of those things.

Here is the problem child.