el33t

Super OPE Member

- Local time

- 8:34 PM

- User ID

- 29908

- Joined

- Aug 28, 2024

- Messages

- 277

- Reaction score

- 691

- Location

- Poland

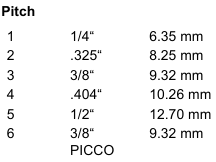

Comparisons to 2x4s or 'foot long' hot dogs are rather risky IMHO.‘3/8’ pitch is a nominal measurement; like 2X4’s, or ‘foot long’ hotdogs.

View attachment 448200

100’ x 12” / foot =1,200 inches

1,200 inches / 1,640 Drive Links = 0.73 inches per link. Divide by 2 to get actual pitch of 0.365” (not 0.375”).

(*** Don’t share this with folks who are easily triggered! Next you will have to tell them where the REAL ‘rakers’ are on the cutters, and that the gullet doesn’t cut!).

Philbert

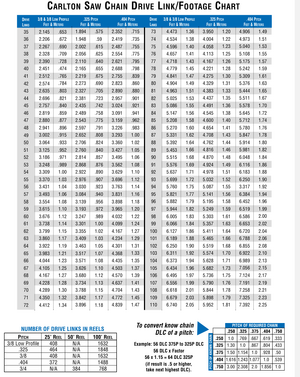

Below is Carlton's chart for different chain lengths. Their “100 ft.” reel has 1632 drive links for 3/8. Which when converted to pitch gives 0.368''.

All these exact conversions to 3 decimal places from a length of 100 ft. only make sense when the roll is actually exactly 100 ft. long.

As an example, Oregon stated that for the 91 the pitch of the cutter link was 0.390'', and for the guide link approximately 0.350'', which averages out to (0.390+0.350)/2'' = 0.37'' without taking into account rivet/openings clearance.

The question is when is the chain pitch measured? Is it in a state when the chain is not under tension or when it is? Normally, on the bar, the chain is tensioned so that fits snugly against the bar and this is the pitch which the sprocket should rather match.

In saw chains we have rivets and hole openings for them in the links. There must be slack between them, otherwise the chain will not work properly (no pivoting). As the chain (or rivets) wears the slack between the rivets and their openings increases, which causes the pitch of the chain to increase as well.

I think we are all familiar with the phenomenon of rapid “elongation” of a new chain at the beginning of its life, and this also applies to chains that are pre-stretched at the factory by the manufacturer. This “elongation” must be equivalent to an increase in pitch.

Sprockets are designed to a “nominal” pitch. The chain pitch and "sprocket pitch" difference must not exceed a certain value, as this can cause undesirable effects like chain chatter and many others.

(Also, of course, any production, even more so mass production, has its tolerances, which are usually included in the technical drawings of the manufactured components.)

If these pitch values of new chains, which are a little smaller (e.g. 0.368") than the nominal size (e.g. 0.375'') , are true, it makes sense, because during the life of the chain, and especially in the beginning, the pitch value will increase. The point is that the difference between the “pitch” of the sprocket and the pitch of the chain should never be too large.