You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20JPX chain?

- Thread starter jake wells

- Start date

- Local time

- 6:04 PM

- User ID

- 786

- Joined

- Feb 5, 2016

- Messages

- 7,820

- Reaction score

- 20,836

- Location

- Here & Now

It's the same just a skip isn't it? I never used any

KenJax Tree

¯\_(ツ)_/¯

- Local time

- 6:04 PM

- User ID

- 359

- Joined

- Dec 31, 2015

- Messages

- 1,953

- Reaction score

- 7,023

- Location

- Over there

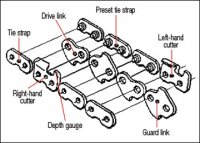

Slightly slower having less cutters, but will clear chips better on buried bucking cuts.

cobey

Here For The Long Haul!

- Local time

- 5:04 PM

- User ID

- 557

- Joined

- Jan 16, 2016

- Messages

- 3,339

- Reaction score

- 11,447

- Location

- Pittsburg, kansas

A couple guys I know love it.

It is slower , a little bit anyway.

I never have used .325 on a long bar

But if did that would be the chain

It is slower , a little bit anyway.

I never have used .325 on a long bar

But if did that would be the chain

SawTroll

Information collector

- Local time

- 12:04 AM

- User ID

- 507

- Joined

- Jan 11, 2016

- Messages

- 730

- Reaction score

- 1,517

- Location

- Troms, North Norway

Basically about 33% slower - but part of that will be compensated by less resistance in the wood (= higher chain speed). Part of it can be compensated by a larger drive sprocket as well, if the saw is strong enough - but then the resistance in the wood also goes up again.

There really is only one way to find the final answer, with a specific operator and saw, in specific wood - trying to calculate it is bound to fail...

I believe a good rule of thumb is to only use skip if chip clearance is the issue - not for any other (expected/theoretical) purpose - unless the saw just is too small and weak for the wood and/or bar length?

There really is only one way to find the final answer, with a specific operator and saw, in specific wood - trying to calculate it is bound to fail...

I believe a good rule of thumb is to only use skip if chip clearance is the issue - not for any other (expected/theoretical) purpose - unless the saw just is too small and weak for the wood and/or bar length?

Last edited:

SawTroll

Information collector

- Local time

- 12:04 AM

- User ID

- 507

- Joined

- Jan 11, 2016

- Messages

- 730

- Reaction score

- 1,517

- Location

- Troms, North Norway

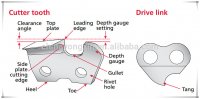

The lack of bumpers on the drivers hardly is an asset, when you have those large ramped rakers instead (and more vibes as well, as it is Carlton chain).

Last edited:

OldJack

Super OPE Member

- Local time

- 5:04 PM

- User ID

- 609

- Joined

- Jan 19, 2016

- Messages

- 171

- Reaction score

- 427

- Location

- Saskatchewan, Canada

Those rakers don't look the same. The lower one is larger.

Those rakers don't look the same. The lower one is larger.

They are the same. You're not seeing the complete top cutter since it is on the back side of the chain.

OldJack

Super OPE Member

- Local time

- 5:04 PM

- User ID

- 609

- Joined

- Jan 19, 2016

- Messages

- 171

- Reaction score

- 427

- Location

- Saskatchewan, Canada

When I said cutter I was referring to the complete cutter piece which includes the depth gauge. You cannot see the whole cutter so it appears the top one has a shorter depth gauge. Just look one of your chains and you will see the same thing.

SawTroll

Information collector

- Local time

- 12:04 AM

- User ID

- 507

- Joined

- Jan 11, 2016

- Messages

- 730

- Reaction score

- 1,517

- Location

- Troms, North Norway

Look at the rakers, not the cutters.

To me the different appearance looks like a result of "optical illusion", caused by what is "seen" (and not) from the camera, how the chain is held, and the lighting?

OldJack

Super OPE Member

- Local time

- 5:04 PM

- User ID

- 609

- Joined

- Jan 19, 2016

- Messages

- 171

- Reaction score

- 427

- Location

- Saskatchewan, Canada

Mea Culpa, I was mistaken. I played with a chain, flexing it back and forth until the light came on. The bump on the rear link's raker is hiding behind the drive link when the chain is straighted out. It looks like the Stihl chain on my MS-170 which I don't use that much, compared to the Oregon chains I've got. The Oregon's don't have that bump.

Similar threads

- Replies

- 0

- Views

- 215