Willard

Here For The Long Haul!

- Local time

- 1:25 PM

- User ID

- 3011

- Joined

- Apr 13, 2017

- Messages

- 1,285

- Reaction score

- 6,763

- Location

- Manitoba

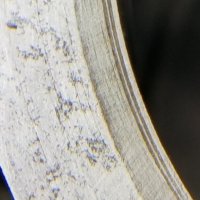

I measured the sleeve thickness in the CR250 and if I bored it out completely I would end up with a 72mm aluminum bore.

From what I can see with the sleeve removed the ports would basically retain their same dimensions.

So can I get the aluminum cylinder bore plated with say nikisel?

Then I would have 300cc with a square 72mm×72mm engine?

From what I can see with the sleeve removed the ports would basically retain their same dimensions.

So can I get the aluminum cylinder bore plated with say nikisel?

Then I would have 300cc with a square 72mm×72mm engine?