angelo c

Coal Member

- Local time

- 4:55 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

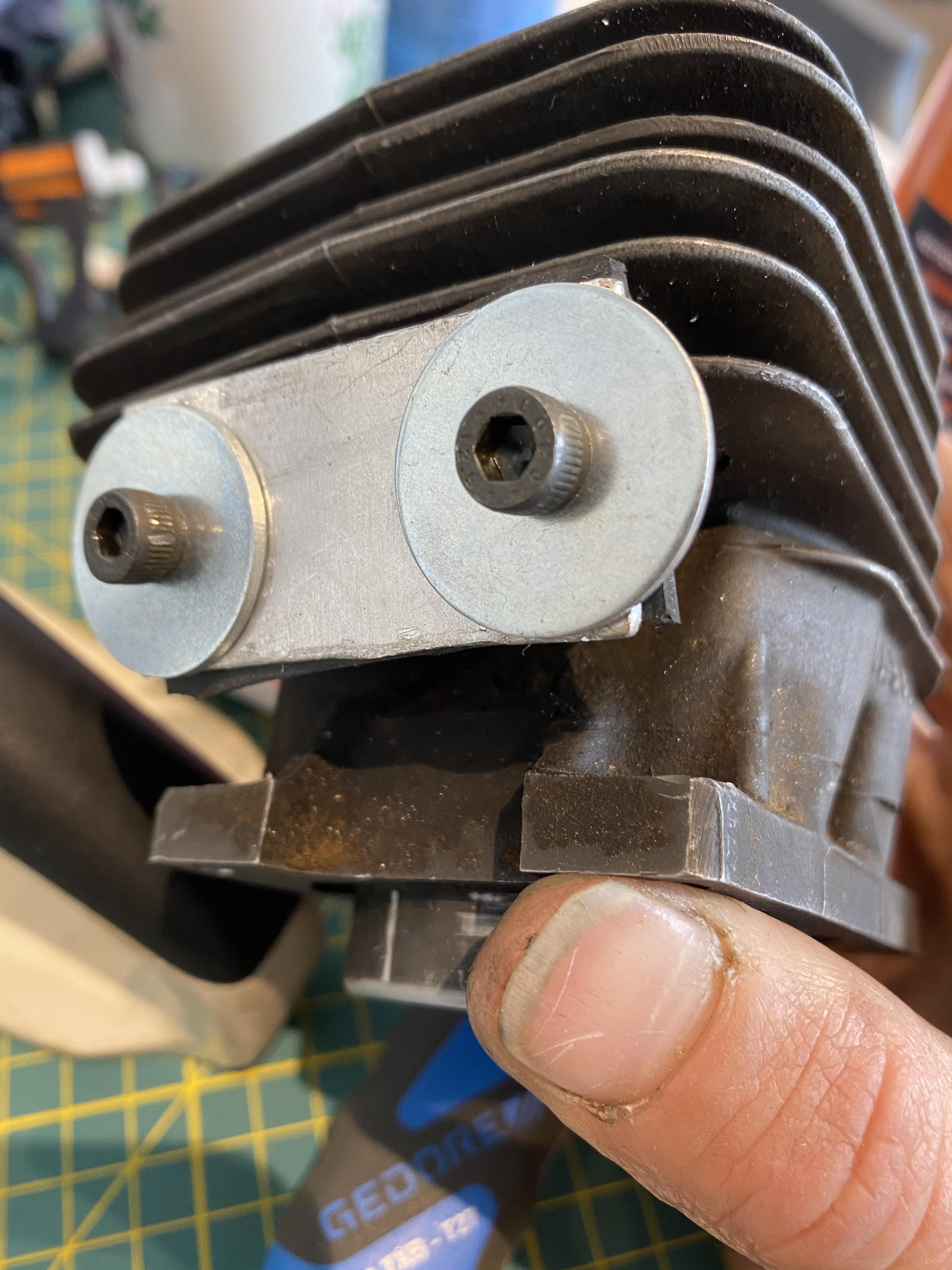

Pry the caps/covers off the muffler screw holes in the center of rhe muffler. The bolts are t27

Porting means that the ports in the cylinder (OEM or AM) have been modified to optimize performance.

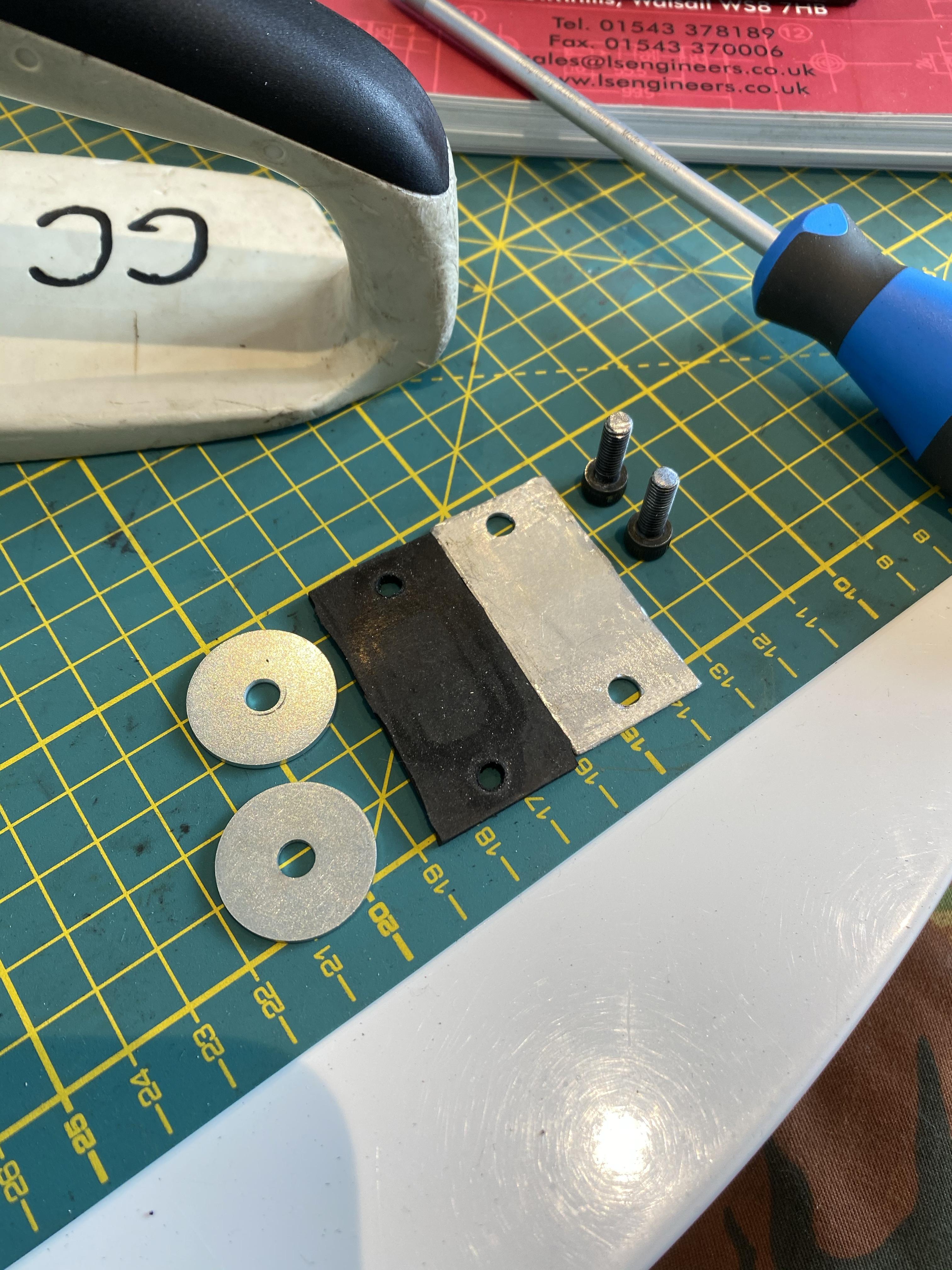

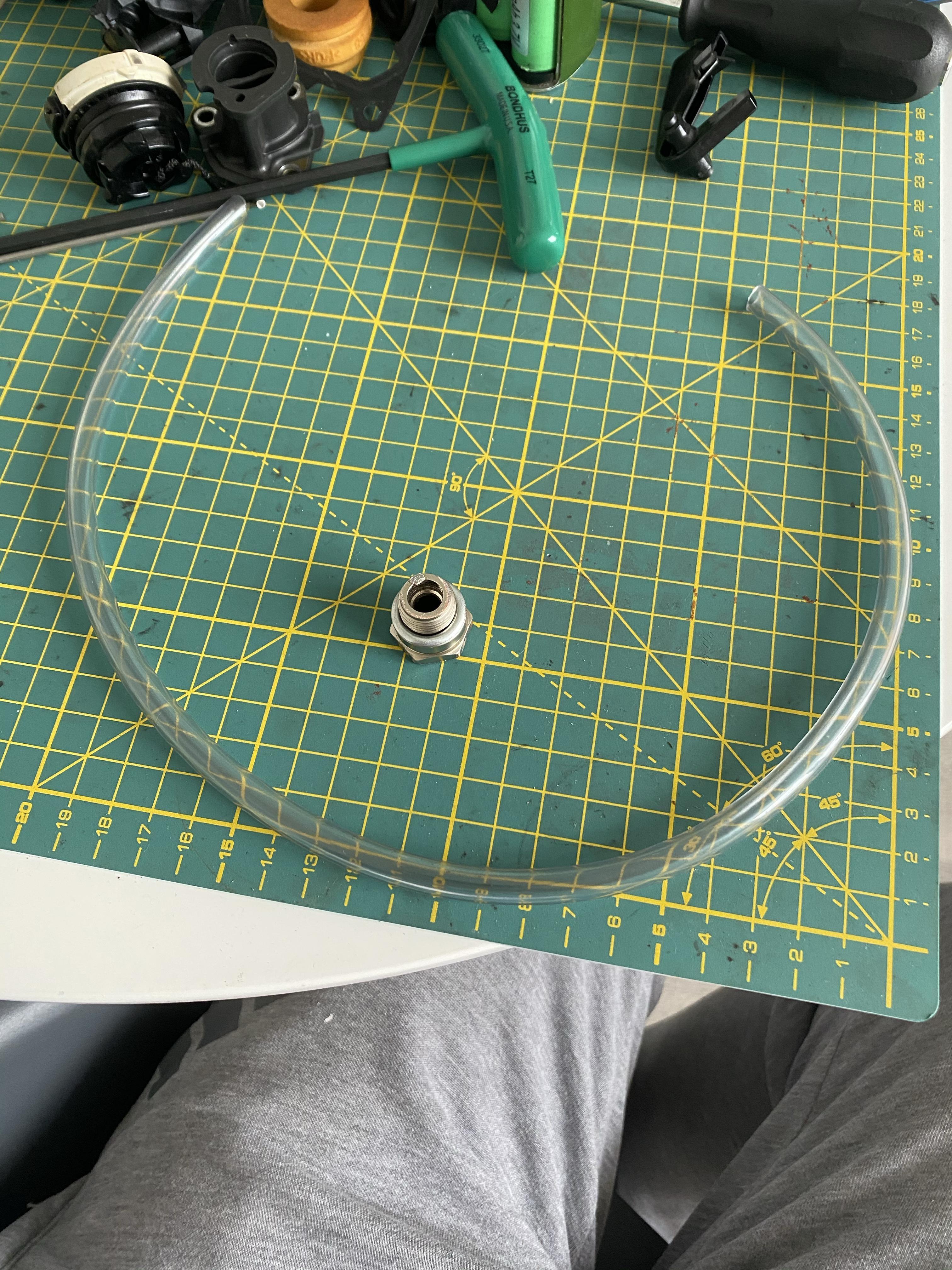

To Vac/Pressure test a saw, you must seal the exhaust port, intake port and hook something to the impulse line (like this).

I believe this is the devise that is most commonly used by folks on this site: (don't go over 10 psi).

https://www.amazon.com/Mityvac-MITMV8500-Silverline-Automotive-Vacuum/dp/B0002SQYUA/ref=sr_1_3?dchild=1&keywords=vacuum+pressure+tester&qid=1593188147&sr=8-3