- Local time

- 1:20 AM

- User ID

- 1377

- Joined

- Jun 5, 2016

- Messages

- 31,070

- Reaction score

- 194,202

- Location

- Northwoods of Wisconsin

There are a lot of in-depth 2-stroke tuning references out there that are mentioned here. While they are very interesting, it seems that only some of the information directly translates to a saw's engine when fitted with a muffler as opposed to a tuned pipe.

The ratio of squish area to total bore area is interesting, as is the angle (if any) between the squish band and the crown of the piston, how that transitions into the combustion chamber and the volume of that chamber.

I am building an 066 to eventually use, but this is the first saw I will build that I don't need yesterday for firewood and other stuff, so I am doing it for fun when I have time. The variables mentioned above are fun to think about but I wonder if I am chasing a 15% gain or a 1% gain over just cutting the squish band parallel to the piston so its wider, cut the base to get the squish back and putzing with the ports.

Thats what I did on my first two saws and they run great, to me at least. Has anyone experimented with optimizing the chamber volume or its shape? Are different diverging angles used on the squish band?

The more I read about this stuff the more I want to just cut the head off this cylinder so i can try all these things with different heads.

Good question. Just like a coin has two different sides to it, a piston has two very different jobs at each end of its stroke TDC & BDC.

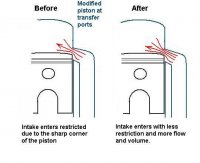

I've yet to see a domed piston and squish band perform better at the bottom. It's much easier to effectively clear spent gasses with a flat top piston. This it seems outweighs any advantage at the top of the stroke.

I did just cut part of the dome on an experimental cylinder that needed such work done. Otherwise it would be counter intuitive to making more compression normally. Other than knocking down the corner edge if it turns out sharp between the band and the dome if the cast radius is removed.

These are just some of the opinions I came to from my experimentation, it shouldn't however discourage yours by any means. Some times something new can be learned if it was just tried out once. Even if that something doesn't work out as planned you have still learned what not to do.