- Local time

- 3:17 AM

- User ID

- 25442

- Joined

- Nov 16, 2022

- Messages

- 257

- Reaction score

- 923

- Location

- Long Beach, IN

Second tank at 40:1 mix tuned to 13,000 RPM for more cutting

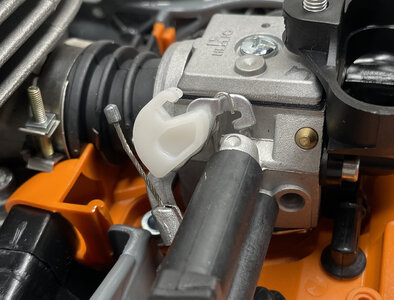

Felt very strong in red oak, then I noticed this after a few slices:

Installed the Stihl decomp valve @drf256 sent me a few months ago for a G660 build and kept on cutting. Ordered a new Husqvarna 503 71 53-01 OEM decomp valve.

Excellent throttle response, new discharge hole and deflector on top of the muffler do a good job of pushing exhaust away from the operator

This is a strong saw that handles very well.

Felt very strong in red oak, then I noticed this after a few slices:

Installed the Stihl decomp valve @drf256 sent me a few months ago for a G660 build and kept on cutting. Ordered a new Husqvarna 503 71 53-01 OEM decomp valve.

Excellent throttle response, new discharge hole and deflector on top of the muffler do a good job of pushing exhaust away from the operator

This is a strong saw that handles very well.

Last edited: