Jimmy in NC

Pinnacle OPE Member

- Local time

- 12:32 PM

- User ID

- 57

- Joined

- Dec 23, 2015

- Messages

- 1,994

- Reaction score

- 8,011

- Location

- North Carolina

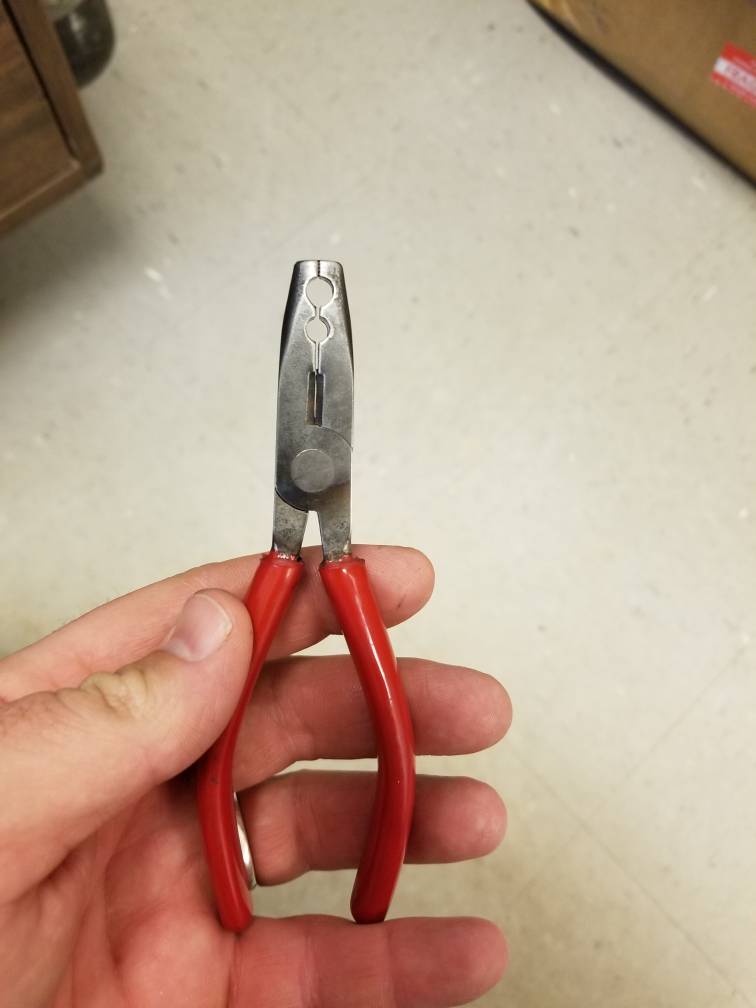

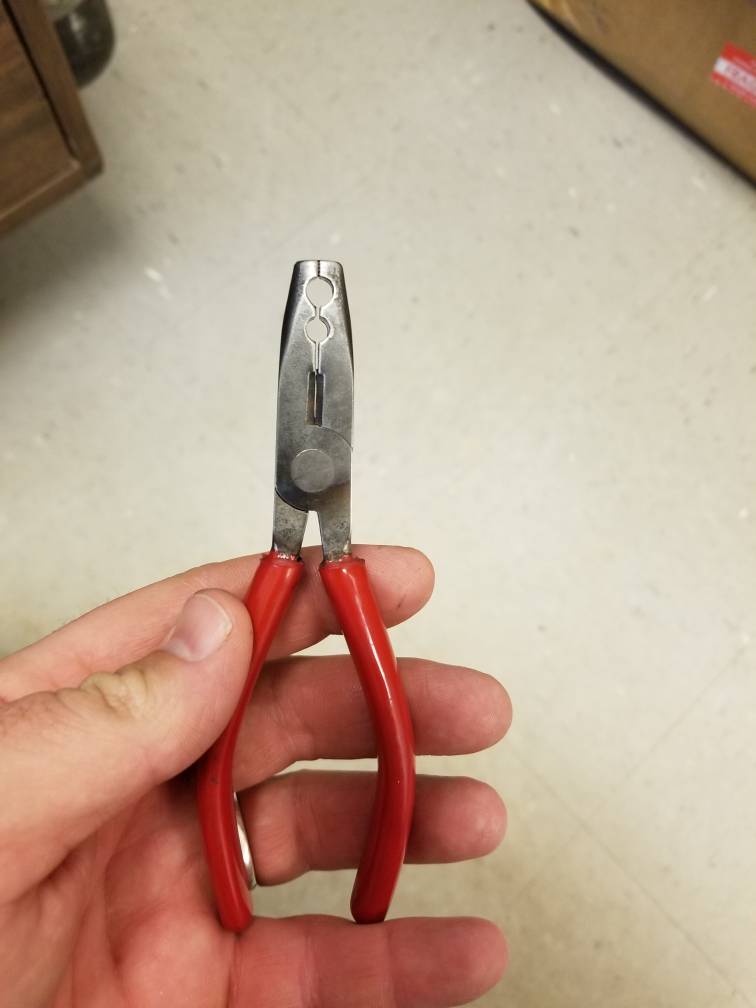

OK. I think anyone that has ever worked on one of the Stihl oilers that requires the semi-rigid plastic tubing will admit they can be a little tricky. I have heat, I have heard a dab of oil, I have heard "read the manual and make the pliers." I am still waiting on the tubing kit but figured I should get prepared for battle. The last time I battled the tubing was over 8 years ago and I still remember it as an experience..

So the factory service manual states to simply drill a 5.5mm hole through a pair of pliers... hmm... ok. I know @Mastermind has done this so I e-mailed and he said with a drill press and good bit, no worries. OK...

First 5.5mm converts to ~.002" under 7/32. Pick up a few 7/32 bits, low drill speed, clamped the pliers in a vise. No joy. I quickly chowdered two brand new decent bits. Feck. Back to scratching my head...

Talking to a few good friends I brought up "Why not take the temper out." They agreed you could do this easy enough. I tried once more before upping my game with an honest drill press instead of the 250lb gorilla press.. still it was a no bueno.

Time to get serious. A tack weld on the tip of these Chinese needle noses to keep them together securely. Check. Now off to find my favorite wrench, the red one! Heated the Top Ramen right out of these Chinese pliers to an International Harvester Red and let them air cool. Back into the vise and OMG kids... hot knife in butter. While at it I dropped back and popped another hole in at 3/16. If an issue with the 7/32 size I can easily open up the smaller hole to fit the line better (I still do NOT have a line kit here...).

Next I just zipped the tip with a cut off wheel. Now these bad boys open once again. From there to everyone's favorite part launcher, the bench grinder and wire wheel. Hanging on for dear life I buffed, deburred, and rounded the edges with out impaling my self with my newly made Stihl Service Tool.

I think with a propane torch and a cordless drill one could easily do this in a home shop. Heat each leg seperate to cherry red and let air cool slowly. Then clamp the pliers securely in a bench vise and get to it. Trimming the end is not 100% necessary but I think it will make life nicer working with and less risk of sticking it solidly through my hand.

Once I put these bad boys into action I'll report how they worked but my experience is that most procedures that Stihl spells out.. work pretty well.

So the factory service manual states to simply drill a 5.5mm hole through a pair of pliers... hmm... ok. I know @Mastermind has done this so I e-mailed and he said with a drill press and good bit, no worries. OK...

First 5.5mm converts to ~.002" under 7/32. Pick up a few 7/32 bits, low drill speed, clamped the pliers in a vise. No joy. I quickly chowdered two brand new decent bits. Feck. Back to scratching my head...

Talking to a few good friends I brought up "Why not take the temper out." They agreed you could do this easy enough. I tried once more before upping my game with an honest drill press instead of the 250lb gorilla press.. still it was a no bueno.

Time to get serious. A tack weld on the tip of these Chinese needle noses to keep them together securely. Check. Now off to find my favorite wrench, the red one! Heated the Top Ramen right out of these Chinese pliers to an International Harvester Red and let them air cool. Back into the vise and OMG kids... hot knife in butter. While at it I dropped back and popped another hole in at 3/16. If an issue with the 7/32 size I can easily open up the smaller hole to fit the line better (I still do NOT have a line kit here...).

Next I just zipped the tip with a cut off wheel. Now these bad boys open once again. From there to everyone's favorite part launcher, the bench grinder and wire wheel. Hanging on for dear life I buffed, deburred, and rounded the edges with out impaling my self with my newly made Stihl Service Tool.

I think with a propane torch and a cordless drill one could easily do this in a home shop. Heat each leg seperate to cherry red and let air cool slowly. Then clamp the pliers securely in a bench vise and get to it. Trimming the end is not 100% necessary but I think it will make life nicer working with and less risk of sticking it solidly through my hand.

Once I put these bad boys into action I'll report how they worked but my experience is that most procedures that Stihl spells out.. work pretty well.

Last edited:

![DSCN0229[1].JPG](/data/attachments/111/111446-83e71354c3c11bc86c1fd8f7aa845d22.jpg)