Wow, you're moving right along, major progress every day.

Rare thing in build threads of any kind here.

Guess you were one step ahead of me on the coupler, another additional reason for using it is that it may help tone down the inevitable and annoying 'scale jitter' a bit (that it looks like you'll soon be experiencing)...

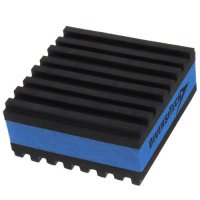

With the very jittery disc brake dyno I went crazy trying to isolate the load cell (scale) to provide some measure of damping, much of it helped but still not enough. After that (and a bunch of software filters) is when I finally gave up on it and switched to hydraulic.