Stackowood

Super OPE Member

- Local time

- 10:21 PM

- User ID

- 2309

- Joined

- Dec 17, 2016

- Messages

- 452

- Reaction score

- 1,100

- Location

- West coast

what threads dimensions do your PTO 372/390 has? (Its stamped in your tool)

I will check when I get back home.

what threads dimensions do your PTO 372/390 has? (Its stamped in your tool)

thanks for the information bud, Ill add up your information in the first postHere is the info for the 372/365 and 385/390 crank tools:

372/365 502503015

385/390 502503017

Both kits have M8x1 internal threads for the flywheel screw, and M14x1.25(V) for the clutch side. The "socket" that comes with the 372 kit seems to work fine on the 390, so you probably don't need both kits.

all you need to know is what threads your Stihl crank has, flywheel and PTO side.Man I love to have a set that will work with Stihl saws. I believe the OEM tools are very pricey from what I have heard.

hi Randy,How did I miss this thread?

Tor, tag me in tech threads please. I've still got a lot to learn.

the socket came with the 346 kit Randy.Did you make that socket Tor?

its the OEM bushing for 550 seals, usuable for 346 PTO seal as well. Let me know if you want the dimensions of the bushing and I'll make a drawing for youI've been meaning to make some of these but I haven't had the time to come up with dimensions for more universal tools. I think I have all the left hand taps I'd need for the PTO side.

It also looks like you have nice seal driver bushings?

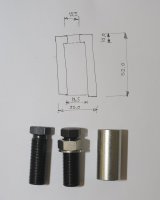

This is the crank mounting tool system that I did set up. Not done yet because I have a few holes to make for the 550 system, but I general two kits cover the whole 50/60cc's line up to Husky. I never needed to buy the 550 kit, my 254 kit already covered it, and with the socket to 346 I ending up to crank the cases together putting the preasure exactly where it should be.

thank youTor that's a great idea to keep them all organized. Mine are all in a plastic bin and it takes some time to find the right ones.

the socket came with the 346 kit Randy.

When I first started to study that 346 socket I realized it was the perfect one, it is a tad under the dimension to seal 505 57 17 19, follow the dimension to the drawing I made, you will probleby never use any other socket when you crank them together.

I mostly deal with larger saws. I'd like to make one for the 288/394/2100 and with one more piece it should be able to do the 395.

Then I suppose I'd have to make one for the 066/660 too.