Wonkydonkey

Plastic member

- Local time

- 7:34 AM

- User ID

- 3189

- Joined

- May 14, 2017

- Messages

- 4,607

- Reaction score

- 18,443

- Location

- Sussex, UK.

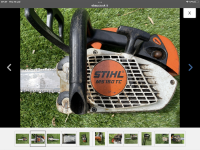

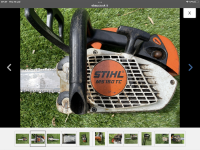

The other day I picked up this Ms150tc, for £155.00. (Edit, $184) I thought it would be a good candidate to add to my list of saws.

I did say “thought”

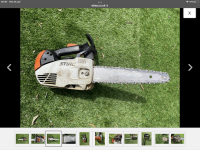

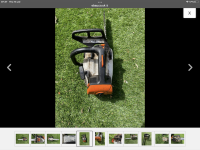

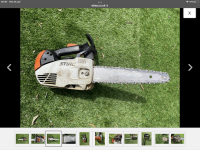

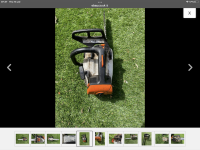

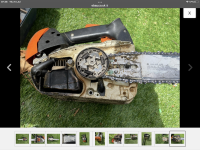

A few pics from the bay.

You can see it’s bounced on the ground in its life.

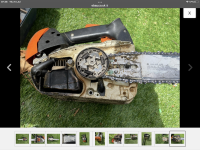

some peeps can’t help to over fill the bar oil, then it all gums up with sawdust over time. .

.

I did say “thought”

A few pics from the bay.

You can see it’s bounced on the ground in its life.

some peeps can’t help to over fill the bar oil, then it all gums up with sawdust over time.