- Local time

- 4:30 PM

- User ID

- 25442

- Joined

- Nov 16, 2022

- Messages

- 253

- Reaction score

- 911

- Location

- Long Beach, IN

Had a bit of fun, learned new things, and got to know some wonderful folks upgrading my vintage 024 AVS in this thread:

https://opeforum.com/threads/stihl-west-german-o24-avs-upgrade-to-44-7-bore.27703/

Decided to have another go at it to build a 16" saw with some leftovers from that upgrade. Received this dead 024 AV the other day from an eBay seller, built May 1986 in West Germany. Six months after the saw referenced above. Parts and fasteners are identical, for example slotted screws used in many places instead of Torx.

Cleaned up real nice:

Bearings and seals are tight, zero side play in the crank.

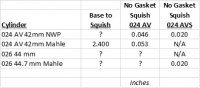

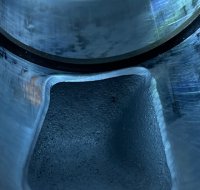

I had hoped to restore the Mahle cylinder it was built with using Randy's method, however it was gouged prettty bad, through the plating and into the aluminum. Squish measured 0.053" without a gasket.

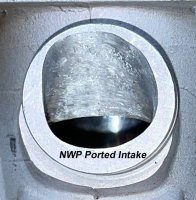

I installed NWP 1121 020 1200 P/C (used previously on the 024 AVS) on the 024 AV without a base gasket. Plan is to run it a bit and maybe upgrade with an OEM piston/cylinder later, perhaps with some mild porting.

Further cleanup revealed the fuel tank has a crack in it, looking for a similar vintage tank and a set of 024 top/filter covers. Installing a new 194 carb as well.

https://opeforum.com/threads/stihl-west-german-o24-avs-upgrade-to-44-7-bore.27703/

Decided to have another go at it to build a 16" saw with some leftovers from that upgrade. Received this dead 024 AV the other day from an eBay seller, built May 1986 in West Germany. Six months after the saw referenced above. Parts and fasteners are identical, for example slotted screws used in many places instead of Torx.

Cleaned up real nice:

Bearings and seals are tight, zero side play in the crank.

I had hoped to restore the Mahle cylinder it was built with using Randy's method, however it was gouged prettty bad, through the plating and into the aluminum. Squish measured 0.053" without a gasket.

I installed NWP 1121 020 1200 P/C (used previously on the 024 AVS) on the 024 AV without a base gasket. Plan is to run it a bit and maybe upgrade with an OEM piston/cylinder later, perhaps with some mild porting.

Further cleanup revealed the fuel tank has a crack in it, looking for a similar vintage tank and a set of 024 top/filter covers. Installing a new 194 carb as well.

Last edited: