Likesaws

Super OPE Member

- Local time

- 6:17 PM

- User ID

- 660

- Joined

- Jan 24, 2016

- Messages

- 325

- Reaction score

- 976

- Location

- South west. Virginia

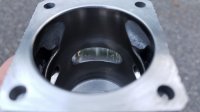

I have a new to me Stihl 026 that I am cleaning and restoring. Very low hour saw still has machine marks on piston and cylinder. Was wondering what most recommend for a stock. I rebuilt the carb and will open up the muffler. Do you recommend a timing advance key way and how much should I take off for stock saw.

Any other recommendations.

Thanks

Any other recommendations.

Thanks