Ronie

Here For The Long Haul!

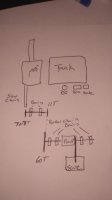

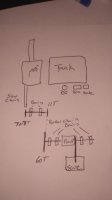

So I've been wanting to build a saw hydraulic dyno for awhile and have finally decided to get busy on it. I'm up in the air about using a scale or just going off the flow rate. On the kart forums it seems like there is the flow crowd and the other crowd that say using a scale is better. That scale crowd says that the fluid will get to hot and the other crowd says that it won't get hot enough to make a difference, anyone have any real life experiences with the two that can shed some light on this? I've ordered most of the parts and something like the pic is what I'm planing, it would be simpler without the scale.

Last edited: