decableguy2000

Pinnacle OPE Member

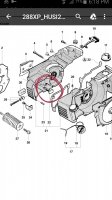

I have a 288 that keeps spitting out one bar stud. It held for a while with a dab of Motoseal, but has come loose again. Other than a case half what kind of options do I have?

I have a 288 that keeps spitting out one bar stud. It held for a while with a dab of Motoseal, but has come loose again. Other than a case half what kind of options do I have?

can't braze mag

My 288 did exactly the same. The bar stud has a square end which fit in the slot inside the oil tank so it won't turn when you tighten the bar. I think its the stud hole of the crank case that hold it only. Once the hole is loose it's gonna dropped in the oil tank and have to be fish out and drop back in. I just use it that way. Just take extra care when loose the nut. It dont even leak bar oil...Not sure what “spitting out” means.

If it’s held by the square area behind it, is it popping into the oil tank or is it spinning around while you try to tighten it?

There are new high temp aluminum braze rod that is reported to work an any non ferrous metal. I’ve been fearful to try it inside because of Mag being known to ignite, I’m unsure if the alloys used in saw cases will do that, but I’ve seen them burn hot white in a camp fire for sure.

Plan is to try it with Tig instead of AZ92A and see if it can be done DCEN.

Any pics?

I love this idea.. Just weld a few spot with steel rod and grind accordingly and press it back in.pull the studs and tin them with solder. that should add a few thow to the dia. hard solder like 95/5 would be best

I drilled and tapped a 3120 case out using time sert and then put Stihl Mid Mount studs in.