buckin-wood

Well-Known OPE Member

- Local time

- 9:12 PM

- User ID

- 10835

- Joined

- Oct 29, 2019

- Messages

- 65

- Reaction score

- 96

- Location

- North East

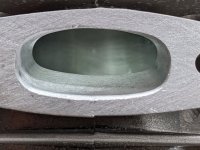

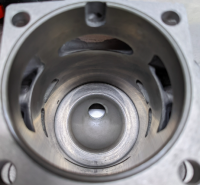

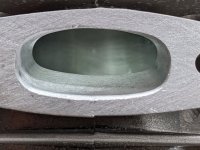

Got a chinvarna 395 and had some problems with the farmetec top end. So I've moved onto a hyway 395 jug with popup piston and started making aluminum chips. As I'm "touching up" the hyway cylinder I realize I have no idea what I'm doing and looking for advise

I found a few posts by folks that have worked oem 395 cylinders and simply copied their recipe... 102/122/82. I'm finishing up the transfers, and have the intake and exhaust mostly done... I think. Hoping folks have some input on a couple questions I'm thinking about before going any further.

-should the sides of the exhaust port flare out/taper more as they approach the muffler flange? any magic ratio of inlet to outlet?

-on the intake side of the lower transfers I took out a large bulge. Now I'm wondering if that casting was intentional to either produce a specific flow pattern or to reduce volume/cross sectional area of the lower transfer

-on the uppers I'm working with the scarr contra handpiece. I've got some touchup to do, but hoping i'm going in the right direction....

I found a few posts by folks that have worked oem 395 cylinders and simply copied their recipe... 102/122/82. I'm finishing up the transfers, and have the intake and exhaust mostly done... I think. Hoping folks have some input on a couple questions I'm thinking about before going any further.

-should the sides of the exhaust port flare out/taper more as they approach the muffler flange? any magic ratio of inlet to outlet?

-on the intake side of the lower transfers I took out a large bulge. Now I'm wondering if that casting was intentional to either produce a specific flow pattern or to reduce volume/cross sectional area of the lower transfer

-on the uppers I'm working with the scarr contra handpiece. I've got some touchup to do, but hoping i'm going in the right direction....