r7000

Well-Known OPE Member

have a stihl 029 saw that has an oregon 18" bar and 3/8" chain.

Chain has some use on it, I filed the teeth then used it once (one tank full) and it cut ok, but not as fast as I think it should have cut. I am thinking the depth gauge of the chain needs cleaning up.

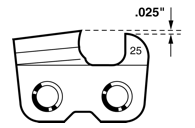

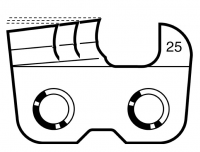

my question is, with or without a depth gauge tool, what is the measurement (as in thousandths of an inch) that the tooth that I normally file to sharpen should protrude above the depth gauge tooth? i.e. I don't want to buy a tool I just wanna run a file on it, how much vertical distance should there be above the depth gauge that exposes the cutting tooth so I have some clue?

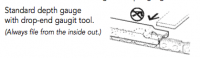

...also, why or how often does the depth gauge of the chain need to be filed? And why? wouldn't the depth gauge wear on its own from use, making having to file it down be rare? What would be the affects if I just went redneck with a file and took off "significant" amount off the top of the depth gauge tooth? Looking for practical info, I've always just run a round hand file, 5/32 or 3/16 on the cutting tooth to sharpen my chains over the years and never had a problem... not a fan of getting all fancy with sharpening tools and schit

Chain has some use on it, I filed the teeth then used it once (one tank full) and it cut ok, but not as fast as I think it should have cut. I am thinking the depth gauge of the chain needs cleaning up.

my question is, with or without a depth gauge tool, what is the measurement (as in thousandths of an inch) that the tooth that I normally file to sharpen should protrude above the depth gauge tooth? i.e. I don't want to buy a tool I just wanna run a file on it, how much vertical distance should there be above the depth gauge that exposes the cutting tooth so I have some clue?

...also, why or how often does the depth gauge of the chain need to be filed? And why? wouldn't the depth gauge wear on its own from use, making having to file it down be rare? What would be the affects if I just went redneck with a file and took off "significant" amount off the top of the depth gauge tooth? Looking for practical info, I've always just run a round hand file, 5/32 or 3/16 on the cutting tooth to sharpen my chains over the years and never had a problem... not a fan of getting all fancy with sharpening tools and schit

Last edited: