Ketchup

Epoxy member

- Local time

- 11:37 PM

- User ID

- 5594

- Joined

- Mar 12, 2018

- Messages

- 1,784

- Reaction score

- 4,960

- Location

- Colorado

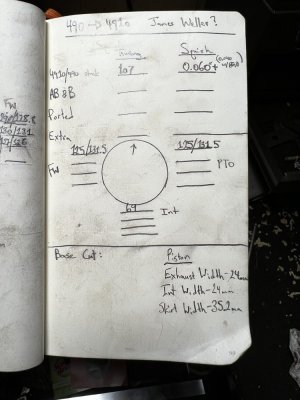

I got this 490 for free. Some folks were saying that a 490 piston might do good things in a 4910 jug, so why not?

I read around to get an idea of where I wanted to go with this saw. I might as well save the next guy some search time:

opeforum.com

opeforum.com

opeforum.com

opeforum.com

opeforum.com

opeforum.com

opeforum.com

opeforum.com

I’ve never been in one of these before.

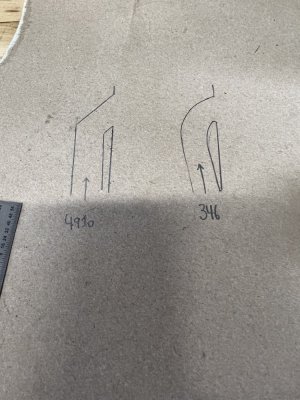

First impression is that the jugs really aren’t that different, but the intake on the 490 is way too low. Transfer uppers are a little undersized in the 490. The 4910 transfer uppers are unusual. 490 has a D chamber.

I read around to get an idea of where I wanted to go with this saw. I might as well save the next guy some search time:

Echo 4910/501p “shortcomings”

As some know, I’m quite a fan of these little guys in ported form. Tons of features I love about them. Some called these a 346 killer, I don’t know about all that but I think it’s a possibility. These saws are consistently hitting 5.5hp on @Red97 ’s dyno, that’s pretty impressive for a $300...

Echo cs 490 porting

Well to keep the clutter out of the 590 thread, I will start this one. First cuts brand new out of the box, limiters, 18" .325 oregon semi chisel. Decent compression sotck. Plenty of skirt on this one, .043 off the base. Better. Piston wash. Pretty much identical to the 500p in...

Another chainsaw dyno...

I'll drop this here. If anyone is interested in dyno service, or any other service. We just launched the site. www.worksaws.com Let me know what you think. I know it needs some tuning yet. Good deal Joe. I'm passing your site to my non OPE saw friends.

Echo 501P. Let's play!

Ok boys. This maybe a super slow build thread. As I really like what im seeing so I may hold off doing any drastic changes till I can sell a couple saws and buy another one. That said. Let's get started. @WSE15 could you post up a few of the exterior pics?

I’ve never been in one of these before.

First impression is that the jugs really aren’t that different, but the intake on the 490 is way too low. Transfer uppers are a little undersized in the 490. The 4910 transfer uppers are unusual. 490 has a D chamber.