- Local time

- 11:53 AM

- User ID

- 10894

- Joined

- Nov 6, 2019

- Messages

- 265

- Reaction score

- 806

- Location

- Salem, Missouri

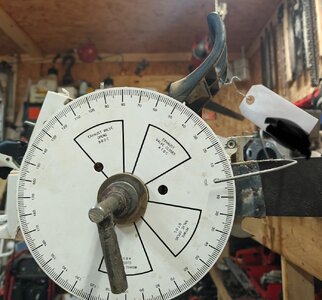

So I figured I'll post this and maybe it'll help someone down the road. If you've ever ported or timed any saws then you had to go through the process of finding a piece of wire and bending it up just right and then find a bolt to secure it under and just pray you don't bump the wire at some point. I ended up with about 20 little pieces of wire in a box and got tired of the time spent messing with it.

So my saw vice I fabricated out of some kind of massive valve out of a bulldozer or locomotive or something huge. I cut a piece of an old Stihl bar off and it's worked very well for hundreds of saws now. It swivels side to side and rotates all the way around. Without the clutch side cover I always just put a couple big washers there to make up for the missing thickness of the side cover to tighten the saws in the vice.

Not long ago I had this bright idea and it has already saved me a ALOT of time setting up timing. I took another old bar and just cut the mounting area off of it. Brazed a piece of pointer wire into that piece of bar and now when I need to setup for port timing I just bolt this new piece on and I'm ready. No more screwing around with pieces of wire laying all over my work bench or looking for a bolt to hold it down.

So my saw vice I fabricated out of some kind of massive valve out of a bulldozer or locomotive or something huge. I cut a piece of an old Stihl bar off and it's worked very well for hundreds of saws now. It swivels side to side and rotates all the way around. Without the clutch side cover I always just put a couple big washers there to make up for the missing thickness of the side cover to tighten the saws in the vice.

Not long ago I had this bright idea and it has already saved me a ALOT of time setting up timing. I took another old bar and just cut the mounting area off of it. Brazed a piece of pointer wire into that piece of bar and now when I need to setup for port timing I just bolt this new piece on and I'm ready. No more screwing around with pieces of wire laying all over my work bench or looking for a bolt to hold it down.