OnlyStihl

Super OPE Member

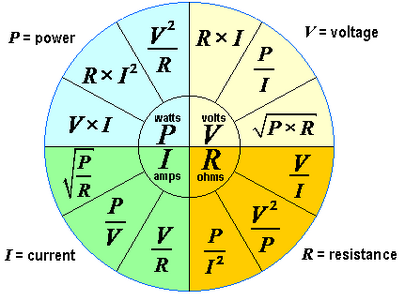

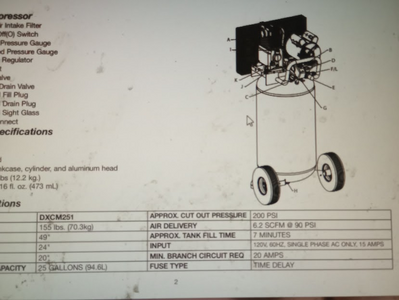

I noticed that my new Dewalt Air Compressor motor is also 240V capable. Simple to do, but I'd have to get into the breaker panel, install a double pole double throw breaker, run some line, mount a receptacle, and change the plug on the compressor, all doable.

What are the advantages? What gain, if any might I see?

What are the advantages? What gain, if any might I see?