Woodslasher

Teh debil

- Local time

- 5:34 PM

- User ID

- 15993

- Joined

- Mar 18, 2021

- Messages

- 3,374

- Reaction score

- 13,637

- Location

- Commiefornia

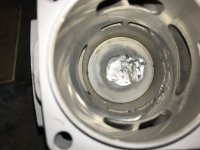

My 461 started running a little funny while I was test running it so I shut 'er down and when I poked at it I noticed the plug seemed a little loose, but when I pulled the plug I noticed the threads looked a little buggered. The plug still threads in fine and I feel like I can get it plenty tight, do y'all think I should worry about it?