- Local time

- 11:44 AM

- User ID

- 29751

- Joined

- Aug 3, 2024

- Messages

- 459

- Reaction score

- 963

- Location

- Oregon

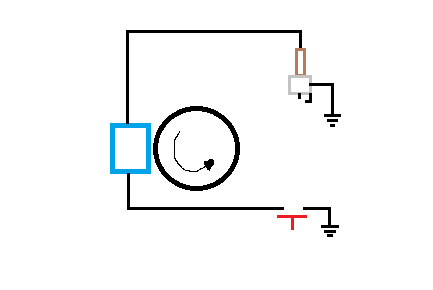

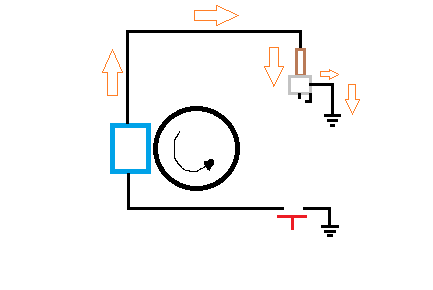

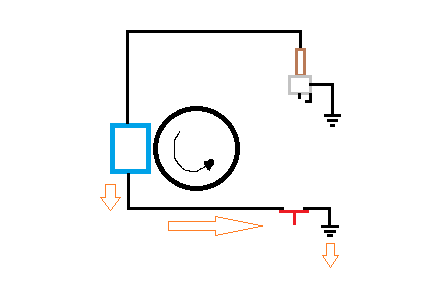

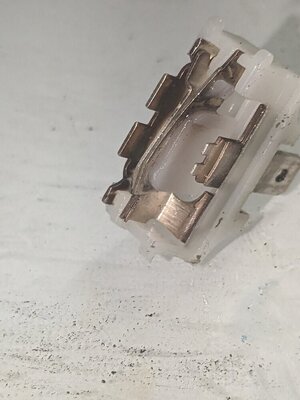

Hello all hope your days going well. I'm a little puzzled at the moment. My 372 isn't getting spark. I've tried 3 coil packs,3 spark plugs, 2 kill switches and changed out the wiring. I've also tried setting ever so slightly different air gaps between plugs and coils, starting with what the repair manual has on the specs section and increaseing/decreasing next size on my feeler gauges. I don't know if this happens(although I assume yes it does) could the magnet in the flywheel loose its ability to connect with the coil? Screws still stick to the damn thing