malk315

Running Saws for Therapy

- Local time

- 12:47 PM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,140

- Location

- Lancaster, MA

I feel bad coming out of the woodwork to ask a question. I'm so behind on OPE lately

One of our 346's was having restart issues amongst other crappy running.

Today I changed fuel line, filter, impulse line, piston good, new muffler that has 2nd port single bull horn.

Set the needles 1 1/4 each and all over the place -- idling weird -- lean, then good, then lean.

WOT was good, then lean, then good. Clearly not right.

Put it aside and came back to it wondering about the tank vent. Pulled the tank vent and voila -- like a whole different saw holds tune perfect, idles perfect, sounds like the 10mm 044 I used to mess with w/ that muffler. Love it.

I can't run it w/ no tank vent -- just piss rev testing in the driveway it's great.

I have this style tank vent w/ no hose connected to it because this is an OE 346 w/ NE Cylinder thus no purge bulb or tank vent to carb box connection which usually connects to these:

It inserts with gray filter towards the tank and that nipple is just there w/ nothing connected.

The carb has just fuel inlet and no others (For purge bulb) it is a genuine Zama EL18B I got new when I had gone through this saw couple years ago.

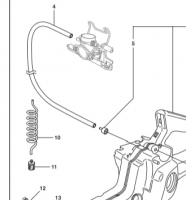

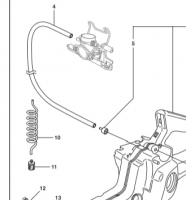

NE 2011 and back 346 IPL shows a hose on this vent -- #5 in the picture below is the vent I included pic of above and is the problematic part:

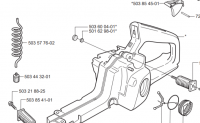

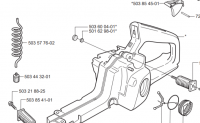

Older IPL From 2001-2006 shows just these two "discs" for the tank vent.

I'm guessing this saw originally had this setup, but it's clear the tank on this saw has the vent w/ the nipple that fits right in really well so I probably need to stick with that. Below is the older IPL:

Questions for you guys are: Is it OK to run w/ the newer style vent that usually has a hose going to a purge bulb or carb or whatever w/ nothing connected? This has run for a while w/ just nothing connected at all to the vent nipple. If that is fine to run that way I'll go with that. Otherwise wondering if there is some kind of hose w/ a screen I should attach to keep debris out?

Tank vents are the most clueless for me. Hence reaching out.

Man what a difference pulling the clearly obstructed tank vent made. I want to run the saw tomorrow so bad because she's ripping, but I'll wait til I get a proper vent as I don't want crap going into the hole where this vent usually goes... Fines could get in there pretty easily w/ that hole exposed that normally has the vent shoved in.

Thanks for any info. Hope all of you guys are well!

One of our 346's was having restart issues amongst other crappy running.

Today I changed fuel line, filter, impulse line, piston good, new muffler that has 2nd port single bull horn.

Set the needles 1 1/4 each and all over the place -- idling weird -- lean, then good, then lean.

WOT was good, then lean, then good. Clearly not right.

Put it aside and came back to it wondering about the tank vent. Pulled the tank vent and voila -- like a whole different saw holds tune perfect, idles perfect, sounds like the 10mm 044 I used to mess with w/ that muffler. Love it.

I can't run it w/ no tank vent -- just piss rev testing in the driveway it's great.

I have this style tank vent w/ no hose connected to it because this is an OE 346 w/ NE Cylinder thus no purge bulb or tank vent to carb box connection which usually connects to these:

It inserts with gray filter towards the tank and that nipple is just there w/ nothing connected.

The carb has just fuel inlet and no others (For purge bulb) it is a genuine Zama EL18B I got new when I had gone through this saw couple years ago.

NE 2011 and back 346 IPL shows a hose on this vent -- #5 in the picture below is the vent I included pic of above and is the problematic part:

Older IPL From 2001-2006 shows just these two "discs" for the tank vent.

I'm guessing this saw originally had this setup, but it's clear the tank on this saw has the vent w/ the nipple that fits right in really well so I probably need to stick with that. Below is the older IPL:

Questions for you guys are: Is it OK to run w/ the newer style vent that usually has a hose going to a purge bulb or carb or whatever w/ nothing connected? This has run for a while w/ just nothing connected at all to the vent nipple. If that is fine to run that way I'll go with that. Otherwise wondering if there is some kind of hose w/ a screen I should attach to keep debris out?

Tank vents are the most clueless for me. Hence reaching out.

Man what a difference pulling the clearly obstructed tank vent made. I want to run the saw tomorrow so bad because she's ripping, but I'll wait til I get a proper vent as I don't want crap going into the hole where this vent usually goes... Fines could get in there pretty easily w/ that hole exposed that normally has the vent shoved in.

Thanks for any info. Hope all of you guys are well!