Charlee cee

Well-Known OPE Member

- Local time

- 11:19 PM

- User ID

- 11880

- Joined

- Mar 3, 2020

- Messages

- 22

- Reaction score

- 203

- Location

- Chandler Arizona

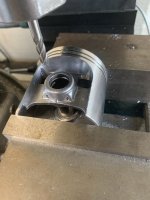

Greetings all. I’ve been a lurker for a while. I don’t have any saws at the moment anymore. But I wanted to share a case reed motor I made with an 090 rotating assembly. It’s for hobby use. Non the less I’d figure I can drop this here. I’m not a very good machinist but I try me best. Moderators, if you feel like this does not belong here, please feel free to take down. I have gotten so much inspiration from your builds it’s my turn to say thank you. This is an almost finished project. Close to firing it up. Second case reed I’ve made using this cylinder.

chinese 090 crank.

Chinese top end (for testing purposes)

Rm65 vforce

Wb23-k4 carb

Home made crank case

Home made manifold

Home made head shell

2 added boost ports.

Custom made pipe

Adjustable timing slide. Since the application is. It saw related I don’t go into detail. naturally my port timings are different. Every hobby has their own way of porting motors. Hopefully you guys can find something useful.

Pictures are not in much of an order as I took them randomly throughout. But I’m sure you guys can figure them out. I have over 200 pics. I can’t upload all of them. But I will try my best to load important ones

this is how it currently sits.

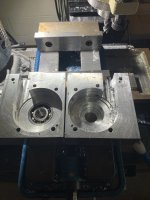

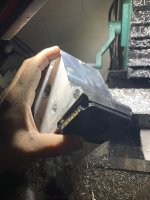

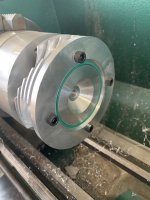

Here are some of the start and machining process.

I can’t upload them all at once. So I will upload the little by little. Again. Mods. If this is not in the right spot. Feel free to remove.

chinese 090 crank.

Chinese top end (for testing purposes)

Rm65 vforce

Wb23-k4 carb

Home made crank case

Home made manifold

Home made head shell

2 added boost ports.

Custom made pipe

Adjustable timing slide. Since the application is. It saw related I don’t go into detail. naturally my port timings are different. Every hobby has their own way of porting motors. Hopefully you guys can find something useful.

Pictures are not in much of an order as I took them randomly throughout. But I’m sure you guys can figure them out. I have over 200 pics. I can’t upload all of them. But I will try my best to load important ones

this is how it currently sits.

Here are some of the start and machining process.

I can’t upload them all at once. So I will upload the little by little. Again. Mods. If this is not in the right spot. Feel free to remove.