Philbert

Chainsaw Enthusiast

- Local time

- 6:13 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 4,438

- Reaction score

- 17,932

- Location

- East Dakota

Plastic bucking and felling wedges are a consumable, but they don't have to be sacrificial. Some of the volunteer groups I work with can be hard on them.

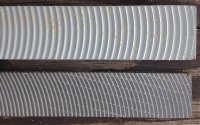

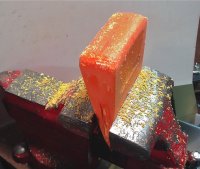

I found it very easy to cut off damaged tips with a bandsaw, or a fine tooth hand saw (coping saw, hacksaw, Japanese woodworking saw, etc.), and to re-shape them with a coarse (60 - 80 grit) belt in a belt sander. The thermoplastic material tends to melt and gob up at the end; cut that excess off with a utility knife, then sand into the belt for a final, smooth finish.

Philbert

I found it very easy to cut off damaged tips with a bandsaw, or a fine tooth hand saw (coping saw, hacksaw, Japanese woodworking saw, etc.), and to re-shape them with a coarse (60 - 80 grit) belt in a belt sander. The thermoplastic material tends to melt and gob up at the end; cut that excess off with a utility knife, then sand into the belt for a final, smooth finish.

Philbert

Last edited: