You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DOLMAR/MAKITA The Official Sachs Dolmar Dolmar Makita Dolmar Chainsaws Thread

- Thread starter Greenthorn

- Start date

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

New member here, hopefully this is the right place. I'm really new to Dolmars, but have recently bought a 105, 111, 153, and electric 219 110v.

The 153 is a running saw with a holed air filter, and the rest of the air filter is just steel mesh, no flock, and is 20 mesh, so lets anything less than 0.92mm through. I'm replacing it with much finer mesh, but otherwise the saw is good. I've bought it as I have a lot of poplar and oaks to deal with, up to 90cm diameter, and I want to do a bit of milling of the poplars as well.

The electric 219 is also a fully working saw. I currently have a florabest (lidl) electric saw in the stables where we buck and split the wood down, it has done a huge amount of work and is still going strong, but I wanted a better electric for this work. Electric is probably not popular on this site, but it is very convenient, and more importantly here in France, extremely cheap compared to running a two stroke saw!

The 111 and 105 were bought as non-runners. The 105's previous owner looked like he was dealing as a side hustle, had never had it running, but it turned over. I stripped and cleaned it all, inc carb, and found that there was no pickup in the tank, and no fuel line to the carb. Return line was still there. I replaced both lines and a new pickup, and it fired into life. When I rebuilt the carb, I set the L and H both to 1 turn from fully in, which was where they were before I stripped it. It was coughing a bit at tickover, so I turned the low to 1.5 turns, and it ticks over happily, revs hard. I've used it to fell and buck a small cherry tree that was hung up after root rot and a storm had finished it, as well as to chop up a lot of pre-pruned branches of oak and maple (I have a 4 stroke Makita pole saw for the pruning).

Anyway, finally onto the reason for my post. I really love this 105, so handy and light but surprisingly powerful. It's clearly done very little work in its life, and I don't want to wreck it, so want to make sure I get this carb set right. I've been using a Homelite XL my Dad rebuilt for the last 10 years, but he is 90 now and not in a state to do the tuning, so now I've got to learn. I understand from the sound of the saw that unscrewing the L and H screws weakens the mixture. Is this correct? If so, how much can I safely weaken it? The high seems a bit rich still, as when the saw gets properly warm it is burbling a bit, but I am scared of leaning it out too much and damaging the piston. Does anyone have approximate settings for this saw?

I've gone through 100 pages of this thread so far and not found any answers by a search, but I probably have missed it.

The 153 is a running saw with a holed air filter, and the rest of the air filter is just steel mesh, no flock, and is 20 mesh, so lets anything less than 0.92mm through. I'm replacing it with much finer mesh, but otherwise the saw is good. I've bought it as I have a lot of poplar and oaks to deal with, up to 90cm diameter, and I want to do a bit of milling of the poplars as well.

The electric 219 is also a fully working saw. I currently have a florabest (lidl) electric saw in the stables where we buck and split the wood down, it has done a huge amount of work and is still going strong, but I wanted a better electric for this work. Electric is probably not popular on this site, but it is very convenient, and more importantly here in France, extremely cheap compared to running a two stroke saw!

The 111 and 105 were bought as non-runners. The 105's previous owner looked like he was dealing as a side hustle, had never had it running, but it turned over. I stripped and cleaned it all, inc carb, and found that there was no pickup in the tank, and no fuel line to the carb. Return line was still there. I replaced both lines and a new pickup, and it fired into life. When I rebuilt the carb, I set the L and H both to 1 turn from fully in, which was where they were before I stripped it. It was coughing a bit at tickover, so I turned the low to 1.5 turns, and it ticks over happily, revs hard. I've used it to fell and buck a small cherry tree that was hung up after root rot and a storm had finished it, as well as to chop up a lot of pre-pruned branches of oak and maple (I have a 4 stroke Makita pole saw for the pruning).

Anyway, finally onto the reason for my post. I really love this 105, so handy and light but surprisingly powerful. It's clearly done very little work in its life, and I don't want to wreck it, so want to make sure I get this carb set right. I've been using a Homelite XL my Dad rebuilt for the last 10 years, but he is 90 now and not in a state to do the tuning, so now I've got to learn. I understand from the sound of the saw that unscrewing the L and H screws weakens the mixture. Is this correct? If so, how much can I safely weaken it? The high seems a bit rich still, as when the saw gets properly warm it is burbling a bit, but I am scared of leaning it out too much and damaging the piston. Does anyone have approximate settings for this saw?

I've gone through 100 pages of this thread so far and not found any answers by a search, but I probably have missed it.

Last edited:

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

Thanks!!

Ronaldo

Pinnacle OPE Member

- Local time

- 5:59 AM

- User ID

- 375

- Joined

- Jan 1, 2016

- Messages

- 868

- Reaction score

- 3,861

- Location

- Eastern Iowa

Wnter weight bar oil is actually a thinner oil. I won't use it in summer as it seems too thin and runny for my liking. In cold temps my bar will only get warm to the touch, but I've noticed when summer cutting, especially long duration dry wood cuts, my bar will get too warm to keep my hand on.

Sent from my SM-S320VL using Tapatalk

Sent from my SM-S320VL using Tapatalk

- Local time

- 5:59 AM

- User ID

- 2014

- Joined

- Oct 21, 2016

- Messages

- 34,438

- Reaction score

- 146,043

- Location

- Kansas

Wnter weight bar oil is actually a thinner oil. I won't use it in summer as it seems too thin and runny for my liking. In cold temps my bar will only get warm to the touch, but I've noticed when summer cutting, especially long duration dry wood cuts, my bar will get too warm to keep my hand on.

Sent from my SM-S320VL using Tapatalk

Ya see I have this other German branded saw that was a weak oiler in hedge for my liking. So a splash of winter blend helped out tremendously.

- Local time

- 5:59 AM

- User ID

- 2014

- Joined

- Oct 21, 2016

- Messages

- 34,438

- Reaction score

- 146,043

- Location

- Kansas

New member here, hopefully this is the right place. I'm really new to Dolmars, but have recently bought a 105, 111, 153, and electric 219 110v.

The 153 is a running saw with a holed air filter, and the rest of the air filter is just steel mesh, no flock, and is 20 mesh, so lets anything less than 0.92mm through. I'm replacing it with much finer mesh, but otherwise the saw is good. I've bought it as I have a lot of poplar and oaks to deal with, up to 90cm diameter, and I want to do a bit of milling of the poplars as well.

The electric 219 is also a fully working saw. I currently have a florabest (lidl) electric saw in the stables where we buck and split the wood down, it has done a huge amount of work and is still going strong, but I wanted a better electric for this work. Electric is probably not popular on this site, but it is very convenient, and more importantly here in France, extremely cheap compared to running a two stroke saw!

The 111 and 105 were bought as non-runners. The 105's previous owner looked like he was dealing as a side hustle, had never had it running, but it turned over. I stripped and cleaned it all, inc carb, and found that there was no pickup in the tank, and no fuel line to the carb. Return line was still there. I replaced both lines and a new pickup, and it fired into life. When I rebuilt the carb, I set the L and H both to 1 turn from fully in, which was where they were before I stripped it. It was coughing a bit at tickover, so I turned the low to 1.5 turns, and it ticks over happily, revs hard. I've used it to fell and buck a small cherry tree that was hung up after root rot and a storm had finished it, as well as to chop up a lot of pre-pruned branches of oak and maple (I have a 4 stroke Makita pole saw for the pruning).

Anyway, finally onto the reason for my post. I really love this 105, so handy and light but surprisingly powerful. It's clearly done very little work in its life, and I don't want to wreck it, so want to make sure I get this carb set right. I've been using a Homelite XL my Dad rebuilt for the last 10 years, but he is 90 now and not in a state to do the tuning, so now I've got to learn. I understand from the sound of the saw that unscrewing the L and H screws weakens the mixture. Is this correct? If so, how much can I safely weaken it? The high seems a bit rich still, as when the saw gets properly warm it is burbling a bit, but I am scared of leaning it out too much and damaging the piston. Does anyone have approximate settings for this saw?

I've gone through 100 pages of this thread so far and not found any answers by a search, but I probably have missed it.

If its burbling out of the cut then cleans up in the cut I'd say you're on the money for tuning.

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

Thanks for the reply. It is doing the opposite, revs normally no load, then starts to burble and bog a little under load, but only when fully warm. Before that, it pulls hard under load without any issues, hence my thinking it was a bit rich on the high? I probably should get a tacho to see what the revs are.If its burbling out of the cut then cleans up in the cut I'd say you're on the money for tuning.

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

I should add that it is still perfectly usable, but it is SO crisp when not fully warm I want to get this performance all the time.

Simondo

Here For The Long Haul!

Welcome to OPE.New member here, hopefully this is the right place. I'm really new to Dolmars, but have recently bought a 105, 111, 153, and electric 219 110v.

The 153 is a running saw with a holed air filter, and the rest of the air filter is just steel mesh, no flock, and is 20 mesh, so lets anything less than 0.92mm through. I'm replacing it with much finer mesh, but otherwise the saw is good. I've bought it as I have a lot of poplar and oaks to deal with, up to 90cm diameter, and I want to do a bit of milling of the poplars as well.

The electric 219 is also a fully working saw. I currently have a florabest (lidl) electric saw in the stables where we buck and split the wood down, it has done a huge amount of work and is still going strong, but I wanted a better electric for this work. Electric is probably not popular on this site, but it is very convenient, and more importantly here in France, extremely cheap compared to running a two stroke saw!

The 111 and 105 were bought as non-runners. The 105's previous owner looked like he was dealing as a side hustle, had never had it running, but it turned over. I stripped and cleaned it all, inc carb, and found that there was no pickup in the tank, and no fuel line to the carb. Return line was still there. I replaced both lines and a new pickup, and it fired into life. When I rebuilt the carb, I set the L and H both to 1 turn from fully in, which was where they were before I stripped it. It was coughing a bit at tickover, so I turned the low to 1.5 turns, and it ticks over happily, revs hard. I've used it to fell and buck a small cherry tree that was hung up after root rot and a storm had finished it, as well as to chop up a lot of pre-pruned branches of oak and maple (I have a 4 stroke Makita pole saw for the pruning).

Anyway, finally onto the reason for my post. I really love this 105, so handy and light but surprisingly powerful. It's clearly done very little work in its life, and I don't want to wreck it, so want to make sure I get this carb set right. I've been using a Homelite XL my Dad rebuilt for the last 10 years, but he is 90 now and not in a state to do the tuning, so now I've got to learn. I understand from the sound of the saw that unscrewing the L and H screws weakens the mixture. Is this correct? If so, how much can I safely weaken it? The high seems a bit rich still, as when the saw gets properly warm it is burbling a bit, but I am scared of leaning it out too much and damaging the piston. Does anyone have approximate settings for this saw?

I've gone through 100 pages of this thread so far and not found any answers by a search, but I probably have missed it.

Just to make sure you get the idea of what the H and L jet screws do and the direction you turn them to make ether a weak or rich mixture.

You start working from the "Basic Settings" of the carb ...L= 1 to 1 and a 1/4 back from seated ..H = 1 back from seated. Get the saw started and idling without the chain spinning (better if you have a TAC to show the actual RPM ) then warm the saw up.

Here is what I want you to grasp....Doing "UP" the L and H screws "WEAKENS" the carb out and not as you put..."unscrewing the L-H "weakens " the carb. So..clockwise = weaker and anti clockwise = richer.

Set the tune with the H screw from the basic setting so there is a slight burble at wide open throttle without load and the saw cleans up once in work.

Last edited:

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

Thank you, that is exactly the opposite of what I thought. I used to race two stroke motorbikes, so I was basing my assumptions on my memories of how the bikes ran, and on those the adjustment screws opened air bypasses to reduce suction on each jet, not on the jets themselves. On this 105, when I do up (clockwise) the L screw, it really sounds like it is getting richer, not weaker, but I will play again with it tomorrow in light of your correction.Welcome to OPE.

Just to make sure you get the idea of what the H and L jet screws do and the direction you turn them to make ether a weak or rich mixture.

You start working from the "Basic Settings" of the carb ...L= 1 to 1 and a 1/4 back from seated ..H = 1 back from seated. Get the saw started and idling without the chain spinning (better if you have a TAC to show the actual RPM ) then warm the saw up.

Here is what I want you to grasp....Doing "UP" the L and H screws "WEAKENS" the carb out and not as you put..."unscrewing the L-H "weakens " the carb. So..clockwise = weaker and anti clockwise = richer.

Set the tune with the H screw from the basic setting so there is a slight burble at wide open throttle without load and the saw cleans up once in work.

Simondo

Here For The Long Haul!

Some fixed jet carbs on saws work just as you say , having a air bleed screw that works as your race bike carbs do.Thank you, that is exactly the opposite of what I thought. I used to race two stroke motorbikes, so I was basing my assumptions on my memories of how the bikes ran, and on those the adjustment screws opened air bypasses to reduce suction on each jet, not on the jets themselves. On this 105, when I do up (clockwise) the L screw, it really sounds like it is getting richer, not weaker, but I will play again with it tomorrow in light of your correction.

The Walbro carb on your saw has fuel passages that are part obscured by the screw needles so clockwise closes the amount of fuel available to be taken into the air flow .

Closing the L down from basic settings should first make the rpm rise as it leans the ratio , and then if you go further the motor will stave of fuel and stop. You will need the L to be rich enough to make the saw transition off idle without much hesitation , so the basic setting is just a "start point". If the saw is free of air leaks... the carb diaphragms are ok and the fuel paths in the carb are free of obstruction , then you should get the carb to tune ok . Do the L side first getting the saw to idle and pick up from idle , then move on to setting the H side to give you the slight 4 stroking sound (burble) at max RPM.

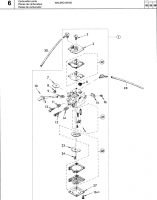

Carb IPL may be of help.

Last edited:

- Local time

- 12:59 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 11,566

- Reaction score

- 44,044

- Location

- Croatia

Mine aren't running at all (2) or poorly (1)  , so I am not really inclined to comment on the fine tuning topic.

, so I am not really inclined to comment on the fine tuning topic.

I need to go through all three of mine and one my neighbor dropped off in a bucket.

But the 105 (top handle) & 108 (rear handle), same PH, are certainly tough little saws.

I have a nostalgic thing for them, especially the 105.

Thanks for pinging me, sorry I'm of no help.

I need to go through all three of mine and one my neighbor dropped off in a bucket.

But the 105 (top handle) & 108 (rear handle), same PH, are certainly tough little saws.

I have a nostalgic thing for them, especially the 105.

Thanks for pinging me, sorry I'm of no help.

Roost426

Super OPE Member

I picked up another really nice 7910 manufactured 2012 but looks to hardly have been used seller said less than 10 hrs, anyways the chain brake doesn't work at all locks forward and back but doesn't hold the chain at all, seller said the band snapped. How much of a bugger is it to replace the band I was reading horror stories on here on some other saws about working on chainbrakes

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

Thanks again, that is clear and I will have a play with it today.Some fixed jet carbs on saws work just as you say , having a air bleed screw that works as your race bike carbs do.

The Walbro carb on your saw has fuel passages that are part obscured by the screw needles so clockwise closes the amount of fuel available to be taken into the air flow .

Closing the L down from basic settings should first make the rpm rise as it leans the ratio , and then if you go further the motor will stave of fuel and stop. You will need the L to be rich enough to make the saw transition off idle without much hesitation , so the basic setting is just a "start point". If the saw is free of air leaks... the carb diaphragms are ok and the fuel paths in the carb are free of obstruction , then you should get the carb to tune ok . Do the L side first getting the saw to idle and pick up from idle , then move on to setting the H side to give you the slight 4 stroking sound (burble) at max RPM.

Carb IPL may be of help.

View attachment 186466

On a slightly different topic, but same 105 saw, fuel priming. From cold it needs around 6-8 pulls to prime the carb with fuel, then fires up on choke, then runs normally. Is this normal? The 153 needs only a couple of pulls to prime, as do the Homelites. I've been wondering if this indicates an air leak in the 105 carb, or whether it would benefit from adding a priming bulb? It only needs the priming pulls if it has been left for a few days, not once it has started that day, even if it is cold again.

On a completely different topic, I noticed our local BricoMarche (Homedepot equivalent) sells red Dolmar saws. The PS222TH for €399, made in Japan, which seems very expensive given that the Makita equivalent can be bought for £230, and the PS32C for €229, made in China. The PS222 looks like a real saw, only smaller, but the PS32 is really nice for a small saw, really well balanced, and plastics feel just as good and solid as the 111. I never used it, just picked it up in the shop, but they also sell some Chinese branded saws for half the price, and the difference in quality was evident. Has anyone used a PS32 in anger? My son is not a fan of chainsaws, though he has used them a lot, but immediately liked the feel of the PS32 and said he would be happy to try it.

hump101

Well-Known OPE Member

- Local time

- 11:59 AM

- User ID

- 9714

- Joined

- Jun 14, 2019

- Messages

- 19

- Reaction score

- 60

- Location

- Corseul, France

Simondo

Here For The Long Haul!

Some saws can take a fair few pulls to fire up from sitting unused , some not, so if the saw runs well once you tune the carb I wouldn't be concerned.Thanks again, that is clear and I will have a play with it today.

On a slightly different topic, but same 105 saw, fuel priming. From cold it needs around 6-8 pulls to prime the carb with fuel, then fires up on choke, then runs normally. Is this normal? The 153 needs only a couple of pulls to prime, as do the Homelites. I've been wondering if this indicates an air leak in the 105 carb, or whether it would benefit from adding a priming bulb? It only needs the priming pulls if it has been left for a few days, not once it has started that day, even if it is cold again.

On a completely different topic, I noticed our local BricoMarche (Homedepot equivalent) sells red Dolmar saws. The PS222TH for €399, made in Japan, which seems very expensive given that the Makita equivalent can be bought for £230, and the PS32C for €229, made in China. The PS222 looks like a real saw, only smaller, but the PS32 is really nice for a small saw, really well balanced, and plastics feel just as good and solid as the 111. I never used it, just picked it up in the shop, but they also sell some Chinese branded saws for half the price, and the difference in quality was evident. Has anyone used a PS32 in anger? My son is not a fan of chainsaws, though he has used them a lot, but immediately liked the feel of the PS32 and said he would be happy to try it.

Dolmar Ps-32 /Makita Ea-3200 are the same saw just colour different.

I use a Ps-32 myself for smaller jobs , very decent cheep saw in my opinion. There 4 spring anti vibe, SS exhaust, adjustable bar oiler, easy start recoil ..purge bulb and MPI coil. They have a Hex port cylinder and run stronger than there 32 cc would suggest. If you remove the Cat in the exhaust this adds to the throttle response as well as giving a little extra power . You can get the saw with bar nuts rather than the hand quick tension cover( works well and not any trouble)...slimmer profile with the nuts .

Last edited:

Simondo

Here For The Long Haul!

No worse , no better , than any band/ spring instal so dont't be put off .I picked up another really nice 7910 manufactured 2012 but looks to hardly have been used seller said less than 10 hrs, anyways the chain brake doesn't work at all locks forward and back but doesn't hold the chain at all, seller said the band snapped. How much of a bugger is it to replace the band I was reading horror stories on here on some other saws about working on chainbrakes

Similar threads

- Replies

- 4

- Views

- 765