Evaluation Update

Been a while so I wanted to post a few things. As noted a few times, I am evaluating the grinder and will not be doing cutting comparisons or videos. A few folks have expressed impatience with the pace of this thread, so I am asking the Mods to refund their OPEforum subscription fees for the month (

@Mastermind).

I was also going to suggest that folks could still buy one of these off eBay with the unconditional warranty, and post their own evaluations, but

@GunTemco beat me to it (these posts were not coordinated!). Seriously, the more input we get, and the more diverse viewpoints posted, the better for our members as well as for the manufacturer. It is their offer, not mine.

A couple of key points:

- This is a

semi-automatic grinder: it runs by itself once set up, but you can't just drop a chain inside and hit the 'popcorn' setting;

- The user still has to understand what a sharp chain looks like, and what they are trying to achieve;

- Like a lot of things, it takes some time and experience to get familiar with the machine and achieve those goals.

I have not been satisfied with the results I was getting, compared to using a manual grinder, so I have not been posting those, and have been trying to understand how to use this machine better. *

Some of it may be me* I may be over-thinking some things, and I may be too focused on my manual grinder experience, which took a lot of time and loops of chain to achieve.

Some of it may be due to the documentation, etc. 'Behind the scenes' I have been sending Gun many pages of comments and input.

Some of it is the design of the machine. E.g. the dual-function control buttons occasionally lead me to mistakes if I hold one too long, and I get a different function, where I have to shut down the machine and start again. Sometimes I turn a knob and nothing happens. I have also experienced one 'fault' where a right hand cutter was ground as a left hand cutter; this happened so fast that I could not intercept and stop the machine. Again, this feedback has been submitted separately.

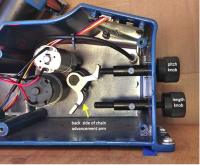

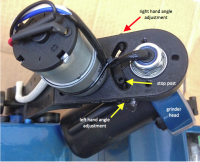

I spoke to Justin at TEMCo today and he suggested that I '

look under the covers' to better understand how the sharpener works (see my next post). I, in turn, suggested that they add a video to their You Tube list of the machine operating without the covers (or with transparent guards), to help users understand the machine, and to also include 'factory reset' positions for all of the threaded knobs, for when someone gets really lost.

I am still confident that I can get good results, once I get the hang of this machine, and have positive expectations for improvements as it moves forward.

Philbert