brandonstclair20

Pinnacle OPE Member

- Local time

- 6:40 PM

- User ID

- 2159

- Joined

- Nov 21, 2016

- Messages

- 940

- Reaction score

- 2,636

- Location

- Starkville

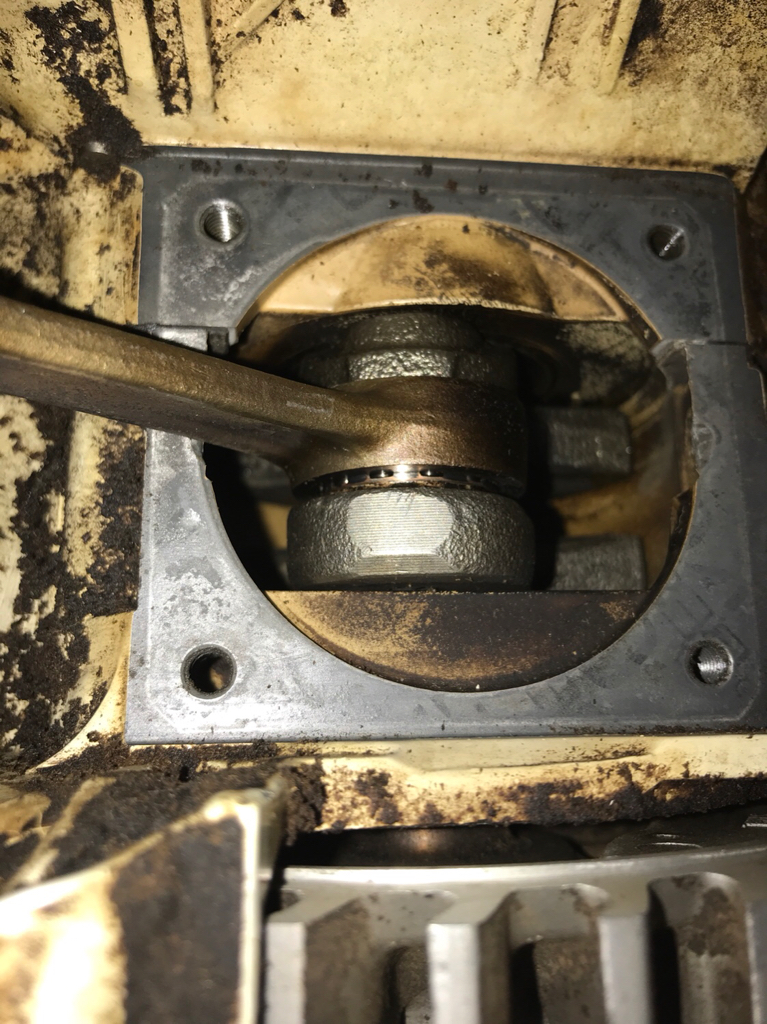

I took the muffler off of a running 064 I just purchased. I saw a scored piston so I took it apart. With some careful work with, fine sandpaper, scotchbrite and a Brillo pad I cleaned up the cylinder. Nothing catches a fingernail. I ordered a new oem piston on Monday. I know an air leak most likely ruined this piston. I closely examined the big end bearing and saw nothing wrong. The crank bearings are smooth. I did not see any debris in the case. I forgot tiny dents in the piston and tiny dents in the roof of the cylinder. What else could be going on here?

Thanks

Sent from my iPhone using Tapatalk

Thanks

Sent from my iPhone using Tapatalk