Kenskip1

Super OPE Member

- Local time

- 12:02 AM

- User ID

- 642

- Joined

- Jan 21, 2016

- Messages

- 146

- Reaction score

- 272

- Location

- Waynesville, Missouri

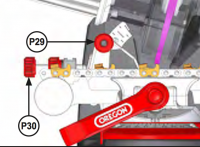

OK,So after putting several tanks through my 025, it was time to sharpen the Stihl RS chain. I am using my "Jolly Star" grinder with the proper size wheel.I am taking off as little material as possible. When I get done it appears as if the teeth on the left side are slightly longer than the right side.I checked this with my Lyman shell case caliper. The left side is around 5-7 mm longer than the right side. I am using 60 degrees on the grinder head, and 30 on the cuter tooth.What am I doing wrong? BTY if anyone asks this is a 16 inch, 325/63 chain.I have sharpened this chain now was the third time.Could the rotation of the motor on the grinder have any bearing?Yes I am picky about how my chains are sharpened. Granted that this is not a large amount but I would like to know what I could be doing wrong.Could the chain have been incorrectly manufactured this way? Yes I am a pain in the arse. I have refused oil filters from my local auto supplier because the filter was out of round. Spark plugs because the electrode was out of center. OK sorry to ramble on.Any suggestions? Thanks, Ken

![20191027_100105[1].jpg 20191027_100105[1].jpg](https://opeforum.com/data/attachments/204/204983-98f808f63dc8a193ed4c316a7403e3c1.jpg)

![20191027_100044[1].jpg 20191027_100044[1].jpg](https://opeforum.com/data/attachments/204/204984-e8d48b2d4abb2274986d3a9a83dba609.jpg)

![20191027_104137[1].jpg 20191027_104137[1].jpg](https://opeforum.com/data/attachments/205/205001-673251f4cf649d54ca24d75b9e7695f3.jpg)

![20191027_112344[1].jpg 20191027_112344[1].jpg](https://opeforum.com/data/attachments/205/205060-2306ede877e16fee66ebaaf3a7ce91a7.jpg)

![20191027_112330[1].jpg 20191027_112330[1].jpg](https://opeforum.com/data/attachments/205/205061-62f0b84beac4c676cf0f8b39b257281d.jpg)

![20191027_111341[1].jpg 20191027_111341[1].jpg](https://opeforum.com/data/attachments/205/205063-a60466abebf88e19c2a77deb0088e624.jpg)