Late to the party, but generally agree with most of the comments.

'Self-feeding' implies that some of the saw's power is being used to pull the chain

into the wood, rather than

through it. It is fun, and can provide some additional degree of control in a cut, but it is inherently inefficient. The top plate edge digs in-between the wood grain (when crosscutting) before the side plate edge has time to sever the fibers.

If a saw has sufficient power to pull that chain, so be it. But the same chain on a lower powered saw may bog down in the cut. So the individual saw, as well as the species of wood, can make a difference. Since you are sharpening your own chain, you can experiment with the angles, hook, depth gauge settings, as others have noted, and see what works for you. Might be different than a guy cutting different wood with a different saw.

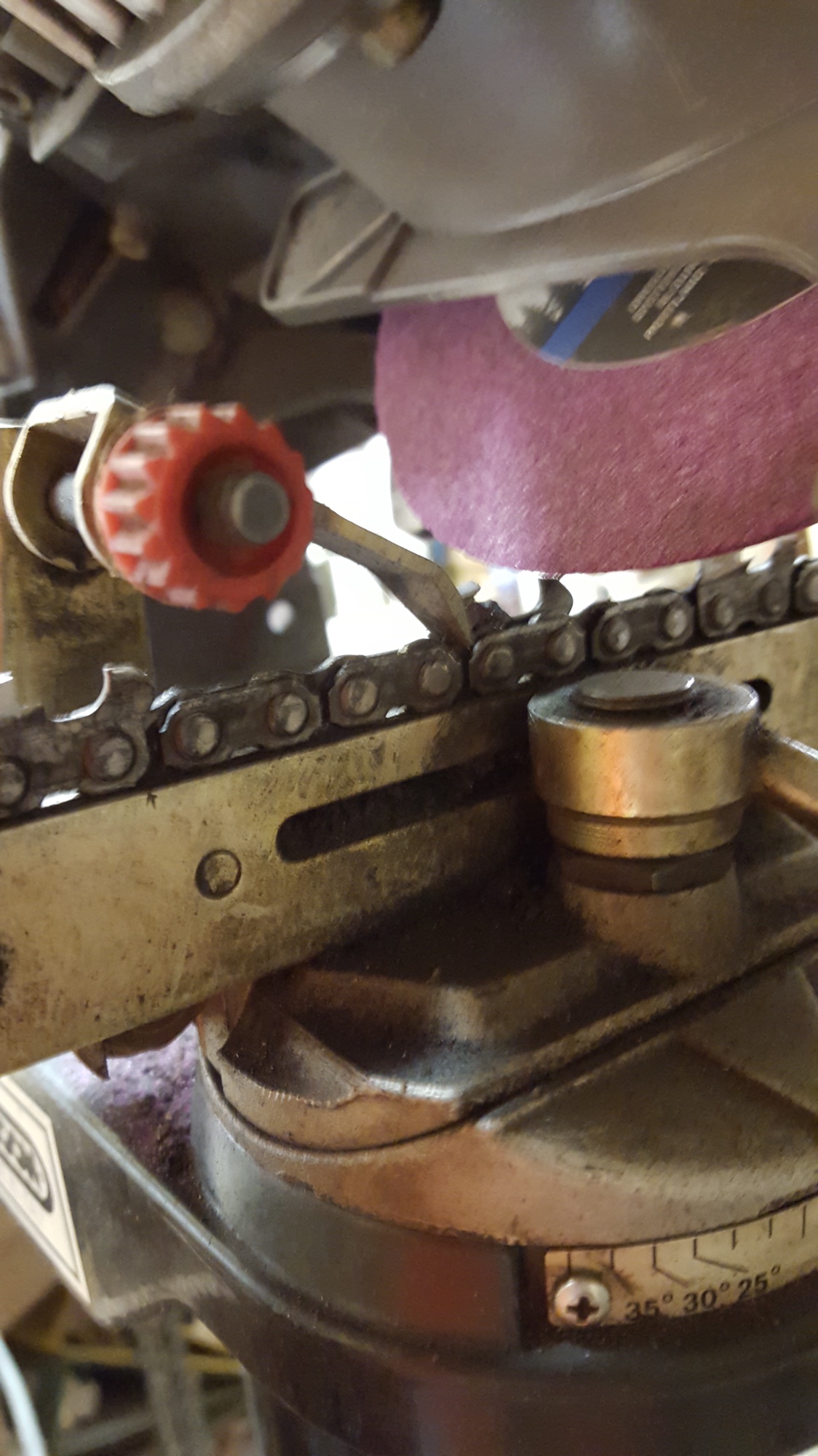

The jury is still out here on grinders but I have seen many ruined chains caused by grinders .

Fair comment. I have also seen many chains ruined by hand filing, that I have to clean up with a grinder. Different R and L angles. Inconsistent angles all over the place. Top plate filed with a top bevel (and not PowerSharp chain!). Filed gullets down to the tie straps but still dull cutting edges.

It is not the tool as much as the person using it.

It looks like I need to pay better attention to my grinding wheels.

Yeah, people do not grasp the importance of dressing the wheels. Frequently.

1. to shape the wheel edge, which then shapes the cutters;

2. to

regularly expose fresh, sharp, abrasive.

I lightly dress the wheel about once per loop, and anytime it stops grinding as well as it should.

Philbert