tree monkey

Mastermind Approved!

- Local time

- 12:56 AM

- User ID

- 339

- Joined

- Dec 14, 2015

- Messages

- 4,818

- Reaction score

- 39,942

- Location

- wi

twas it a bit tinner den ya taut?

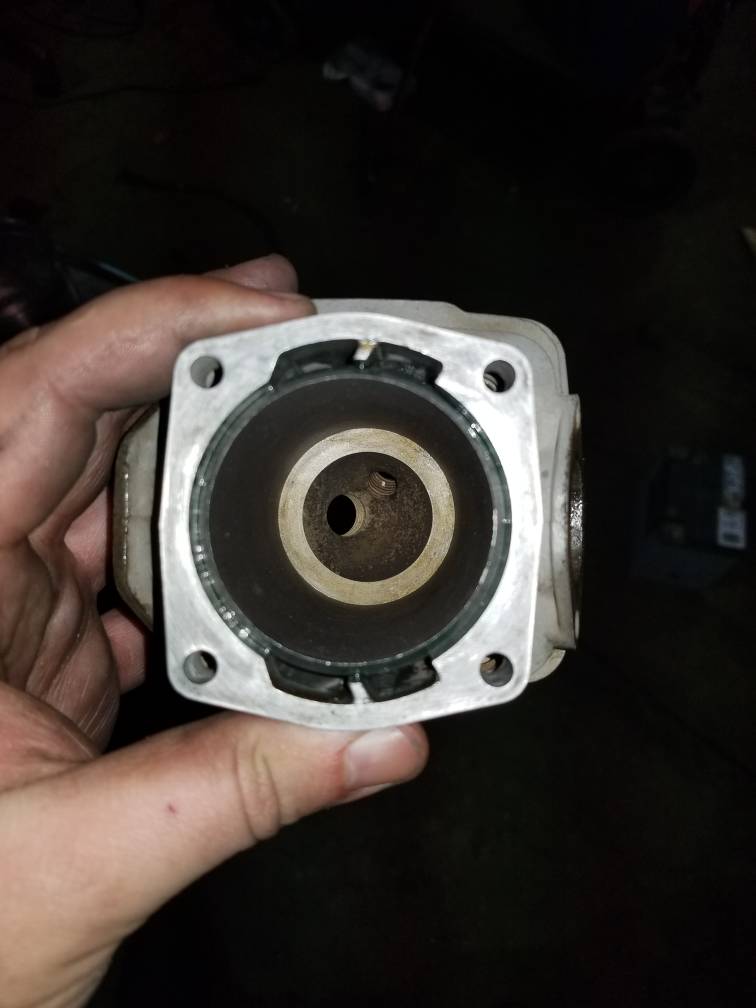

Should be able to set squish now...Well alrighty then...

Piston willm fit now.

Sent from my SM-G950U using Tapatalk

Well alrighty then...

Piston willm fit now.

Sent from my SM-G950U using Tapatalk

Sleeves are usually a tight press fit. Maybe that's what you meant??The sleeve should be interference fit correct?

Yesh...Sleeves are usually a tight press fit. Maybe that's what you meant??

How much shorter than an 044 do you need?

2 mm will get me in the ball park. with a longer skirt.

Sent from my SM-G950U using Tapatalk

272 is taller

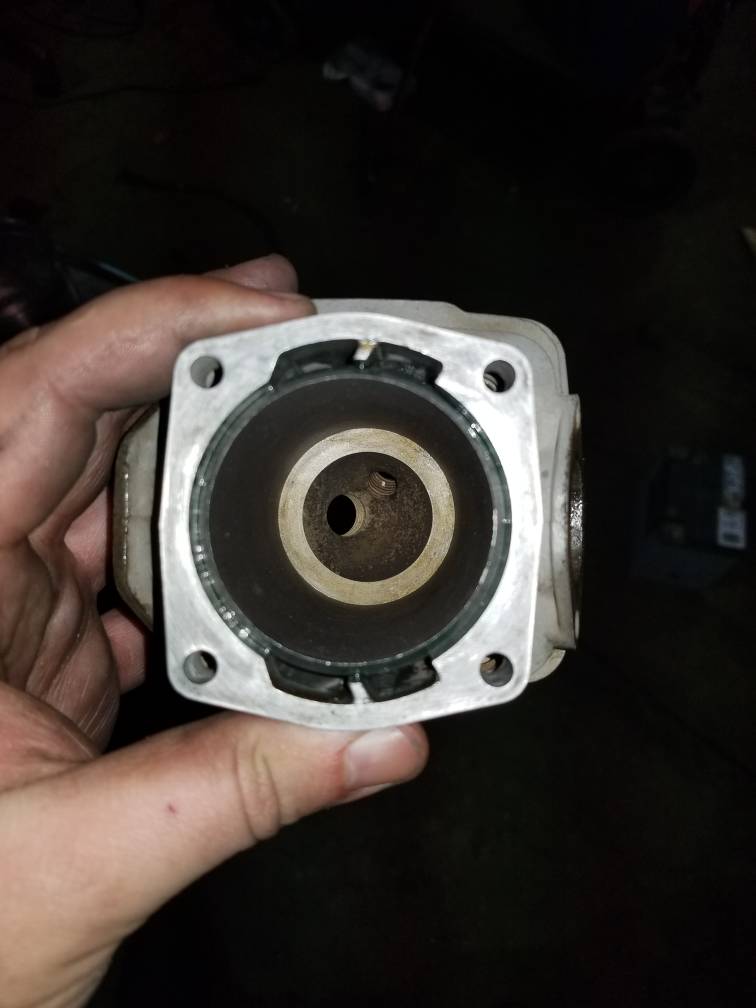

The sleeve was 2.189 od..I knew it was gonna get real thin. Just figured it would have cut through once I got past the extension diameter...

If anybody is wondering the thinnest diameter on the od of a 590 jug is 2.195".

Sent from my SM-G950U using Tapatalk

Exactly. Thank you.Nothing ventured.......nothing gained.

Still the coolest thread I've seen in awhile.

Don't feel like spending the $$ for a 50mm capable sleeve, so I'll finish the 670 jug to fit the 52mm sleeve.What's the next move Joe?

Lol, long studs and jb ftw!!Use long studs like you would on a 2 piece head, cut the sleeve to determined length so your squish is right and run it.

Not yet... still looking for the correct surface finish for red armor.any pics of the pole yet?

Indeed. .001 is what I was i was going for. Had it all the way in then heard a small pop and it kept pressing. LolThe sleeve should be interference fit correct?

Taller than the 372Isnt a 272 right around that?

This ^^^272 is taller

Maybe.. transfer caps and press on cooling fins lolAt this rate Joe I’d just cut what you want out of billet. Cut up some screw on transfer caps. Cut cooling fins while it’s on the lathe. It’s experimental anyway so start with blank sheet.