Carhartt

Super OPE Member

- Local time

- 2:42 PM

- User ID

- 1712

- Joined

- Aug 18, 2016

- Messages

- 654

- Reaction score

- 892

- Location

- Central Pa

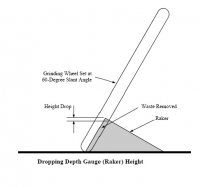

What raker profile works best? Flat top with a rolled over leading edge or a raker ground on say a 55 degree angle with a lower front and higher towards the tooth. Does one way or the other throw the tooth off when in the cut?