Philbert

Chainsaw Enthusiast

- Local time

- 9:18 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 4,434

- Reaction score

- 17,906

- Location

- East Dakota

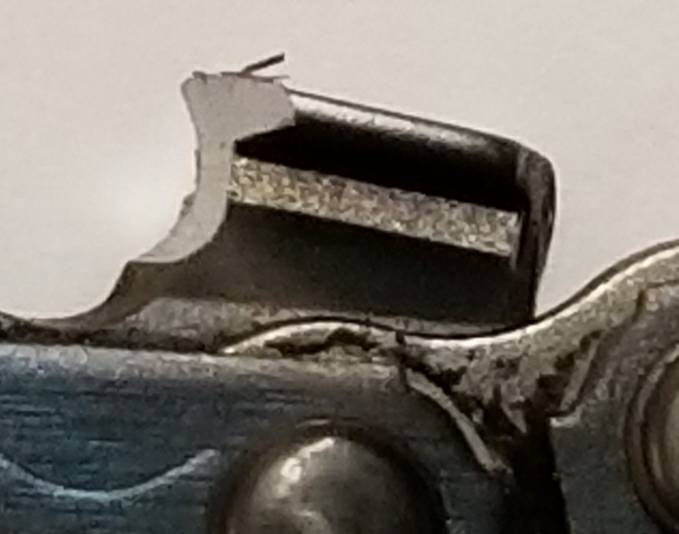

My key word is 'intent': you have to know what you want the final tooth / cutter to look like before you start. Same with a file, Dremel, etc.

If you just run the grinder like a chop saw, you get what you get.

Philbert

If you just run the grinder like a chop saw, you get what you get.

Philbert