jrobie79

Well-Known OPE Member

- Local time

- 2:44 AM

- User ID

- 5925

- Joined

- Apr 17, 2018

- Messages

- 11

- Reaction score

- 18

- Location

- New Hampshire

Someone suggested I take a look at this forum vs other chainsaw forums, and so far I've been impressed... I've beeen reading a bunch and just picked up a new to me ms361, it is absolutely filthy, so far I've probably picked off, wiped, scraped about a full pound of crap. So i started stripping it to clean it. See below:

Before I started tearing it apart I took a compression reading, and got just under 120psi. Is this acceptable? Haven't run the saw at all so I never took a warm reading:

My question is, what should I change while I'm in the process of putting everything back together since it'll be most stripped down? When I work on my car if I have to take a bunch of parts off I might as well swap in new smaller parts (hoses, plastic bits, etc...). I was thinking maybe some seals, rubber bushings, hoses, etc.

I've been using the factory service manual and this forum to take it apart and look forward to my new addiction and bring more active on this forum.

Does this piston look toast? If so, should I go with a genuine Stihl replacement? or any recomended aftermarket? (I've read meteor piston with caber rings?)

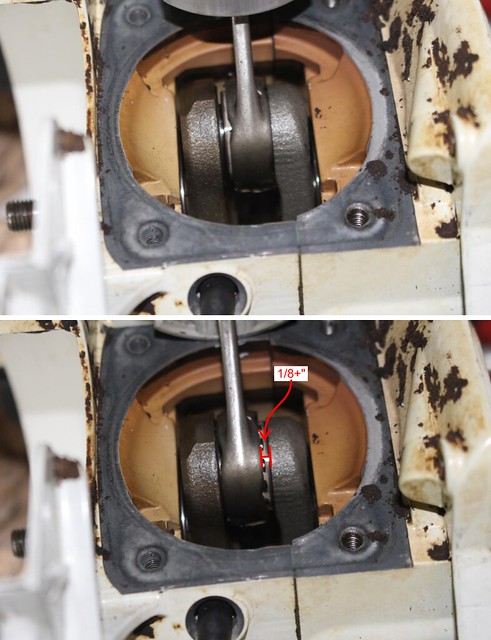

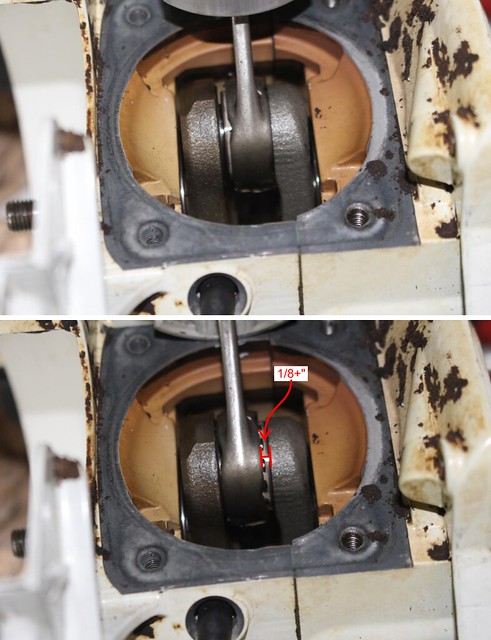

I also noticed there is side to side play in the rod at the crankshaft (shown in photos below), is this normal?

Should I use upgraded (ceramic) bearings? Also, in the IPL it lists two size cylinder gaskets, what's the deal behind one or the other?

Took a few other photos of the clutch side, lot of worn out powdercoating, so I'm gonna split the case and see what I can do to get it re-powdercoated (anyone recomend somewhere to get this done?)

Before I started tearing it apart I took a compression reading, and got just under 120psi. Is this acceptable? Haven't run the saw at all so I never took a warm reading:

My question is, what should I change while I'm in the process of putting everything back together since it'll be most stripped down? When I work on my car if I have to take a bunch of parts off I might as well swap in new smaller parts (hoses, plastic bits, etc...). I was thinking maybe some seals, rubber bushings, hoses, etc.

I've been using the factory service manual and this forum to take it apart and look forward to my new addiction and bring more active on this forum.

Does this piston look toast? If so, should I go with a genuine Stihl replacement? or any recomended aftermarket? (I've read meteor piston with caber rings?)

I also noticed there is side to side play in the rod at the crankshaft (shown in photos below), is this normal?

Should I use upgraded (ceramic) bearings? Also, in the IPL it lists two size cylinder gaskets, what's the deal behind one or the other?

Took a few other photos of the clutch side, lot of worn out powdercoating, so I'm gonna split the case and see what I can do to get it re-powdercoated (anyone recomend somewhere to get this done?)

Last edited: