Lacing is the OEM method and great if you intend on taking the belt on and off. The noise of the lacing hitting the pulleys got to me over the years so I glued it together. I used gorilla glue on mine. I just sanded the ends to a wedge shape to accept the glue and c-clamped between 2 blocks of wood.

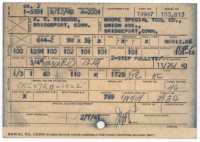

The Model 9 is a good lathe. Do you have the Quick Change gearbox or Power Cross Feed? The 9C had neither, the 9B had the power cross feed and the 9A had both.

I have the cheaper 9C but it works for me, although I'm always on the lookout for a quick change gearbox that isn't priced like gold.

Here is a link to a manual put out by the Army about SB 9 and 10 inch lathes.

http://www.opensourcemachinetools.org/archive-manuals/sb_army_lathe.pdf

A video on the 9C