Leafy

Super OPE Member

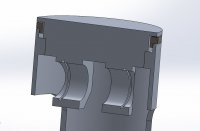

So I came across a few yoututbe videos tonight about 2 stroke piston rings and it dials down to 2 concepts. 1, someone makes a piston ring that is lipped and has a piston dome which screws on to retain it so you can no longer catch a ring on too large of a port. What does that do for you? Exhaust port width can now equal cylinder diameter and no slipped rings. Whats the issue there? If you make such a port the transfer and exhaust will freeport when the wrist pin hole crosses them. Well someone else (mark atkinson) also makes pistons where the outside is full round and a wrist pin holder threads into the underside of the piston (side effect is that they end up being lighter and have better roundness at operating temperature.

So how abouts we make a piston that is basically a skirt with a female thread at the top and a dome which has the wrist pin holder. I cant seem to find the supposed patent that new zealand company has but I didnt look too hard, but even so a few of these to see if its worth anything isnt going to draw any attention. Hardest thing I can see is making a stepped ring like that, best I can come up with is find a very thick ring in the right diameter and carpet tape (or mag vise) it down in the mill to gently cut the step in it.

So how abouts we make a piston that is basically a skirt with a female thread at the top and a dome which has the wrist pin holder. I cant seem to find the supposed patent that new zealand company has but I didnt look too hard, but even so a few of these to see if its worth anything isnt going to draw any attention. Hardest thing I can see is making a stepped ring like that, best I can come up with is find a very thick ring in the right diameter and carpet tape (or mag vise) it down in the mill to gently cut the step in it.