Terry Syd

Pinnacle OPE Member

- Local time

- 11:33 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,973

- Location

- Comboyne, NSW Australia

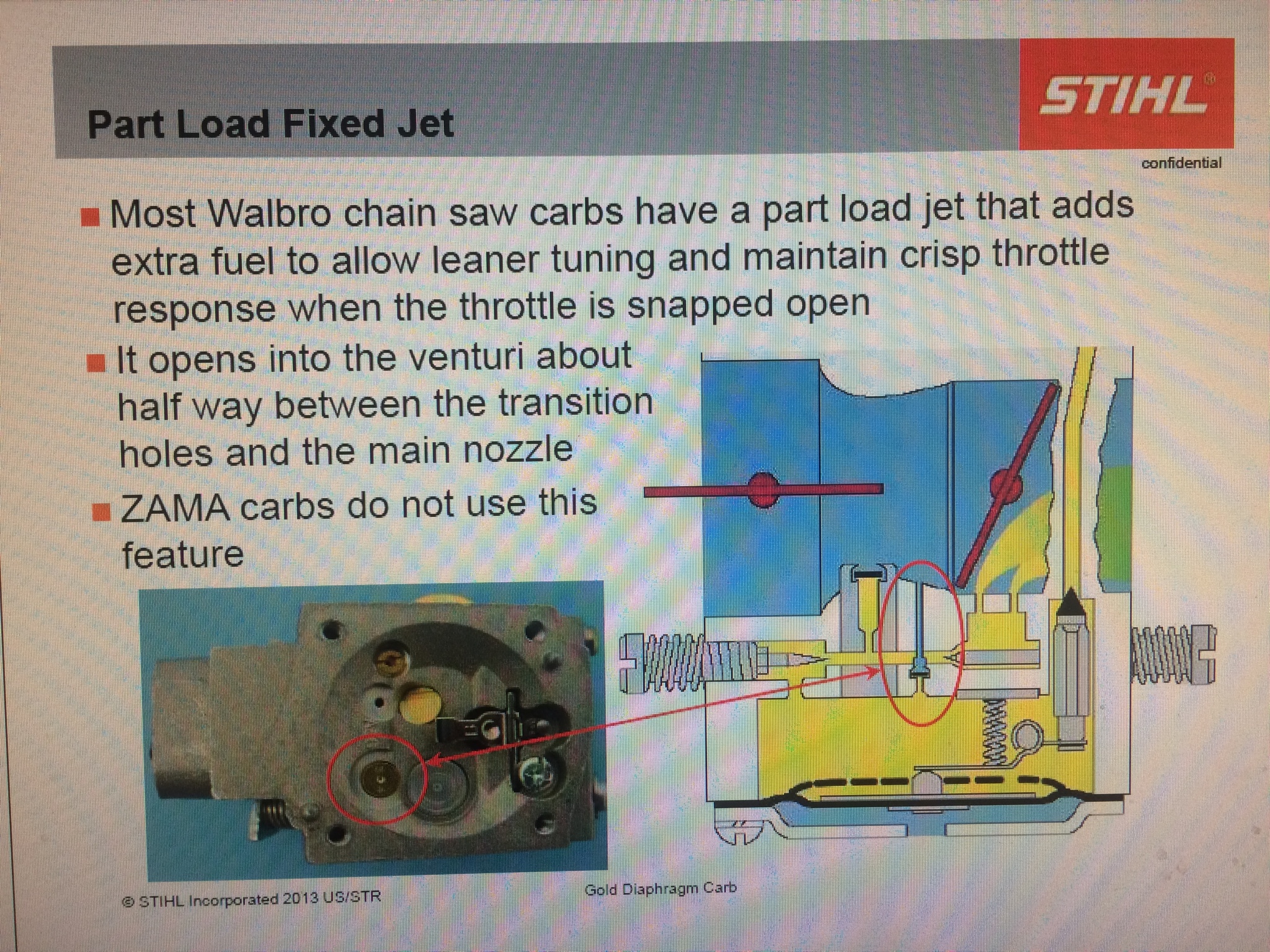

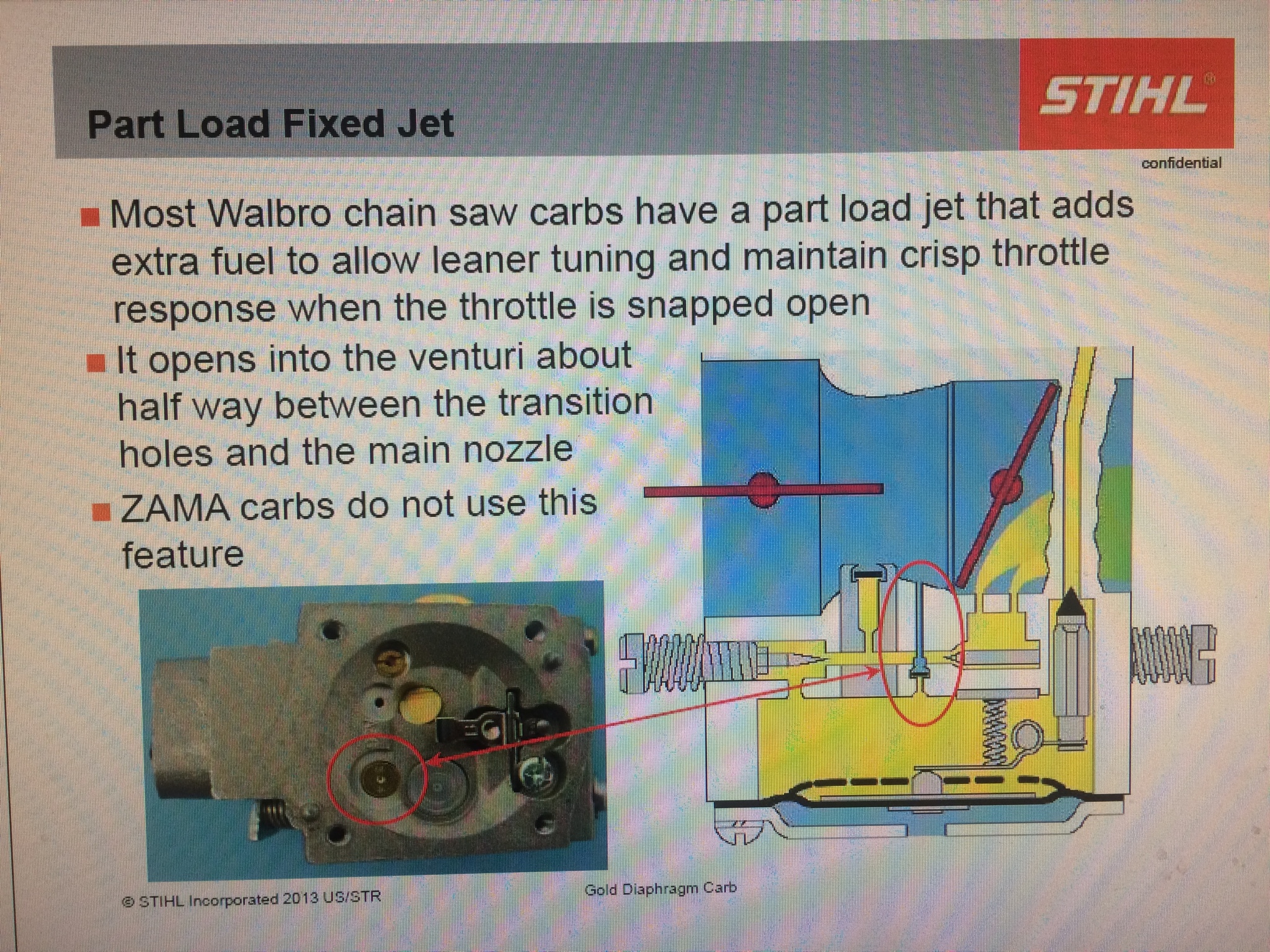

This explanation is incorrect. Where it says "It opens into the venturi about half way between the transition holes and the main nozzle". It actually enters the straight section of the carb body BETWEEN the two transition holes. You can confirm this by shining a light through the hole or spraying some WD 40 through the jet.

Note that the reason they give for the jet is that "to allow leaner running and maintain crisp throttle response" - bugger the 'allow leaner running' bit.