- Local time

- 10:52 PM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 8,933

- Reaction score

- 62,229

- Location

- Coastal Oregon

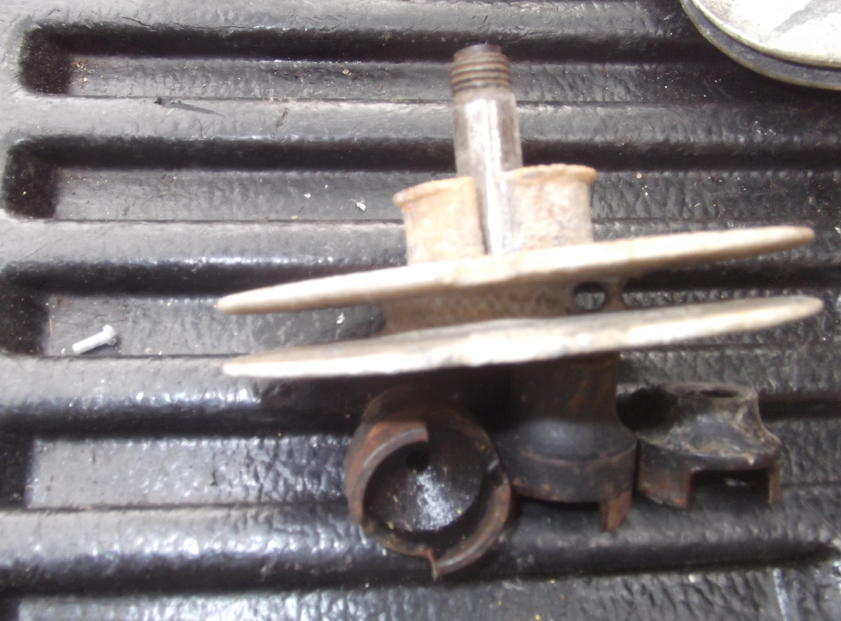

Great write up JJ! Dose that cp block have any number on it? Been curious about that! What muffler did your dad like on the 101?

I am running the 125 crank in my sdc saw, because of mcbob! I have two welded style cranks, one was a cp crank and the other was a 101aa, after seeing so may counter weight issues, I think I will have a buddy fussion Tig the counterweights to have some more insurance!

Looks like maybe a early boost port CP block Jacob? Thanks for sharing this stuff on your dads saw. This is pretty much how my build is going to be.

I think it’s the late style, replacement block, That’s why I’m curious about the numbers

I think it's a late replacement block myself - it has no numbers on it of any kind and I bought a NOS 797 block off ebay a few years ago that is similar. It has the boost port area cast-in but the sleeve

isn't cut for the boost ports. I think my dad put this saw together around '73. I know he bought the 101b engine when it first came out in '74 and had Rich build it straight away and that was his

favorite saw by far. The other SP he built later, probably around '76-77. Before that he was running the straight CP-125s. When he first went to work in the woods ('67 or so), he was running the 100cc Pioneers.