MattG

Chainosaurus Rex

- Local time

- 4:33 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

Hi Husky peeps,

I'm more used to mending stihls, but a friend of a friend wants me to fix up a Husq 142. I received the usual problem report:

"It used to start, now it doesn't, can you help?"

So compression test, only 120 psi, a bit lame, but I'm guessing it should start right? It does have a good spark. But the carb was horrible, full of all sorts of cack. So I've stripped and cleaned the carb, found some MS200T new carb spares to use for new diaphragm/gaskets/needle etc. and I'm gonna throw back together and give it fresh fuel and see what happens.

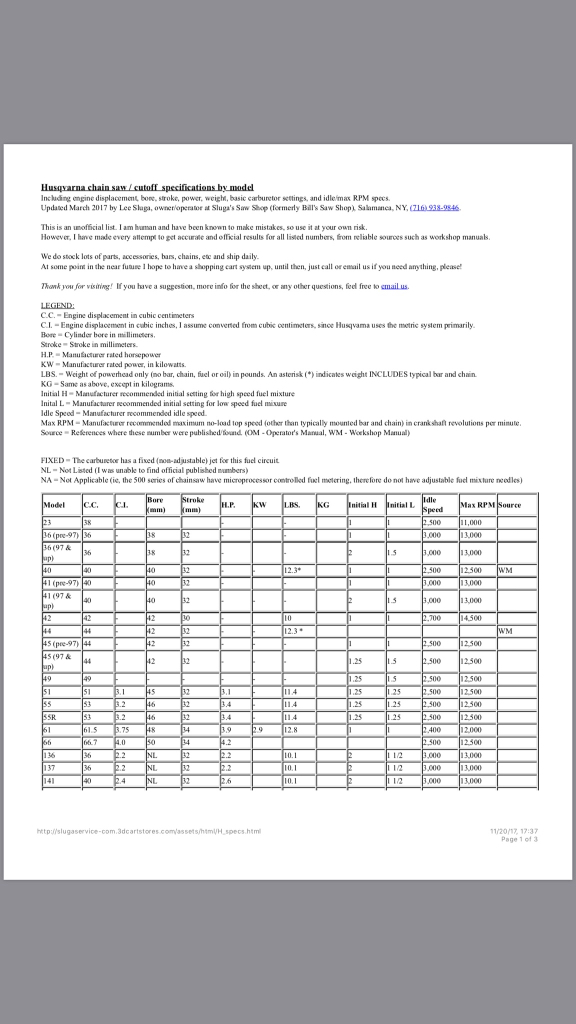

So what baseline setting should I apply to the H and L screws? Can anyone just tell me to starting point (e.g. H screw x turns out, L screw whatever turns out etc. etc.)

thanks in advance!

Matt

I'm more used to mending stihls, but a friend of a friend wants me to fix up a Husq 142. I received the usual problem report:

"It used to start, now it doesn't, can you help?"

So compression test, only 120 psi, a bit lame, but I'm guessing it should start right? It does have a good spark. But the carb was horrible, full of all sorts of cack. So I've stripped and cleaned the carb, found some MS200T new carb spares to use for new diaphragm/gaskets/needle etc. and I'm gonna throw back together and give it fresh fuel and see what happens.

So what baseline setting should I apply to the H and L screws? Can anyone just tell me to starting point (e.g. H screw x turns out, L screw whatever turns out etc. etc.)

thanks in advance!

Matt