malk315

Running Saws for Therapy

- Local time

- 5:52 AM

- User ID

- 421

- Joined

- Jan 6, 2016

- Messages

- 2,101

- Reaction score

- 10,140

- Location

- Lancaster, MA

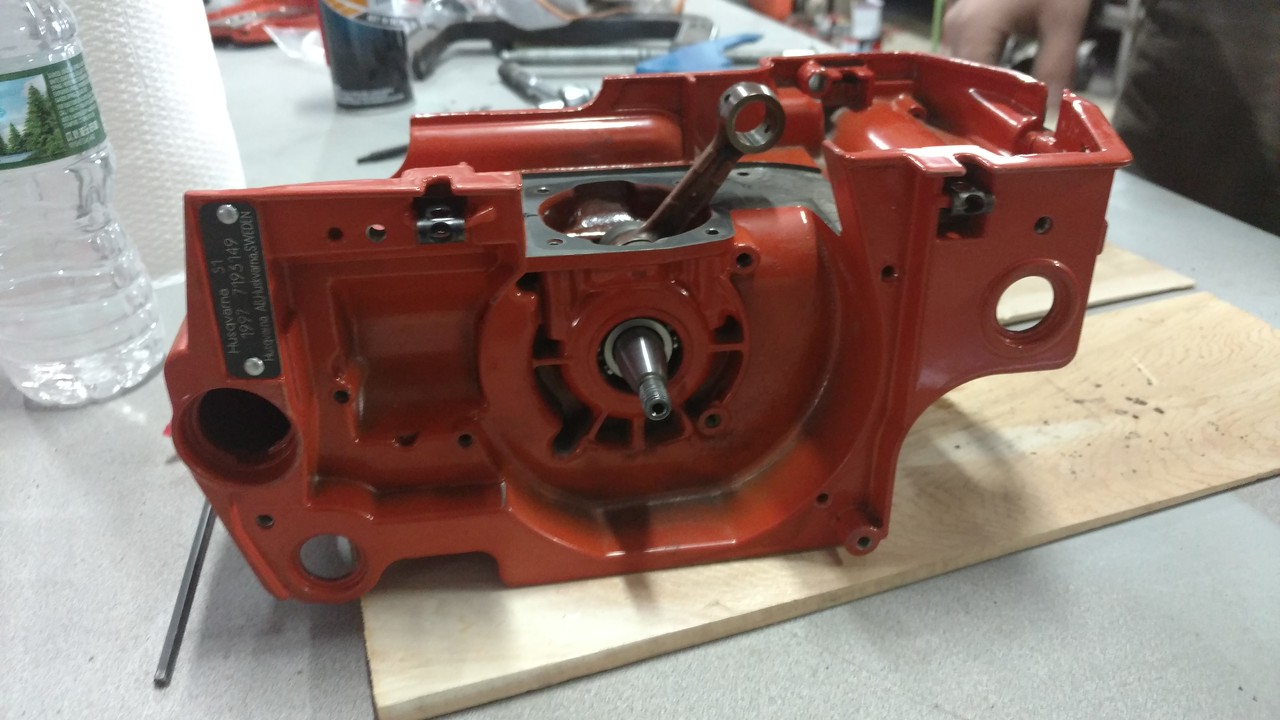

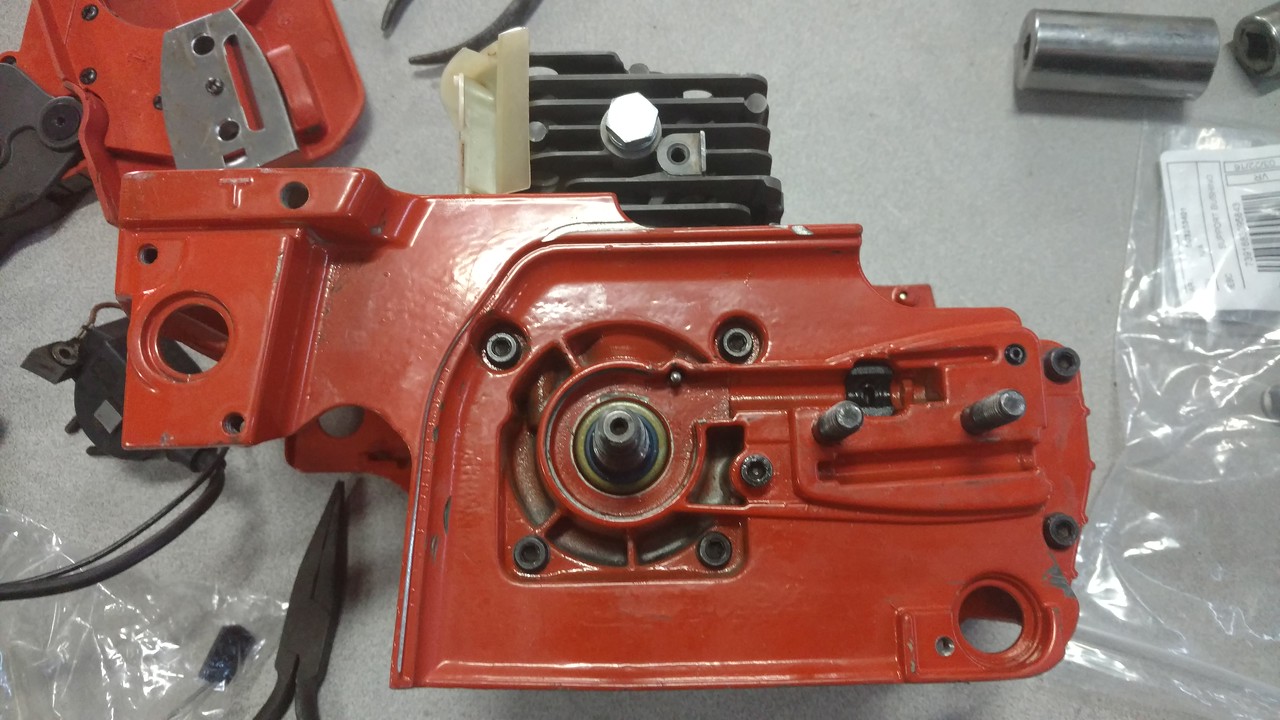

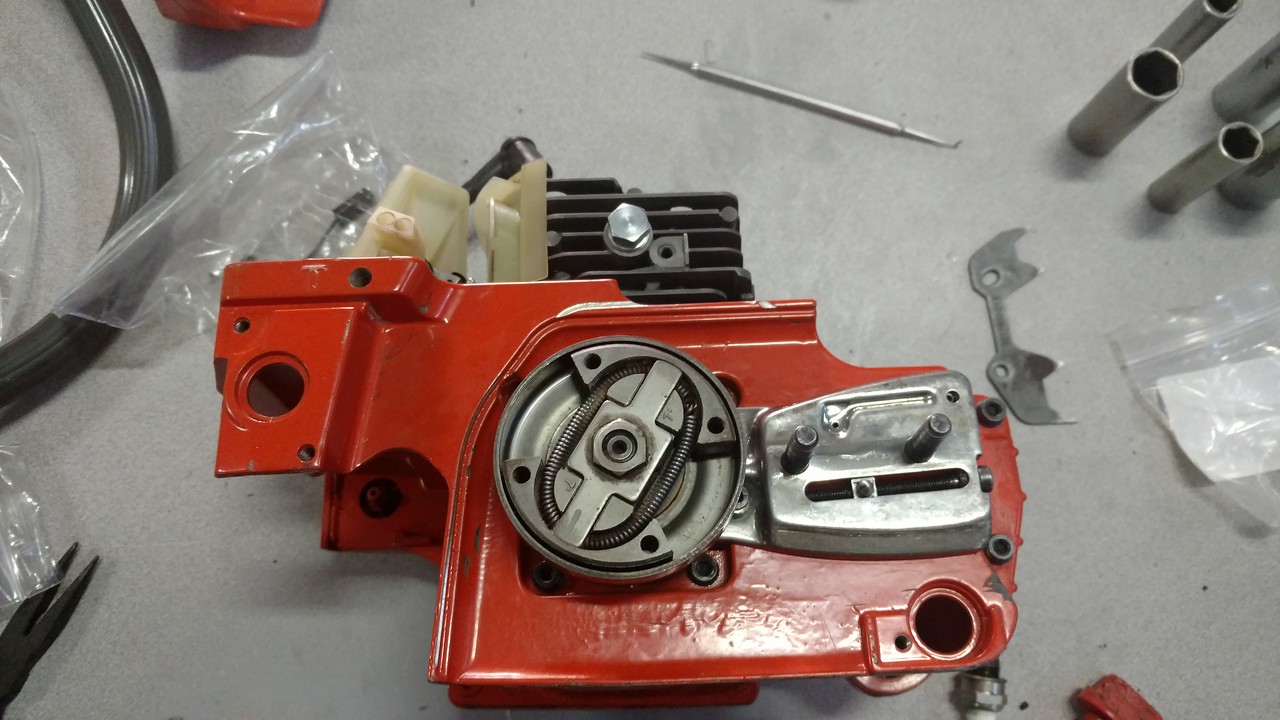

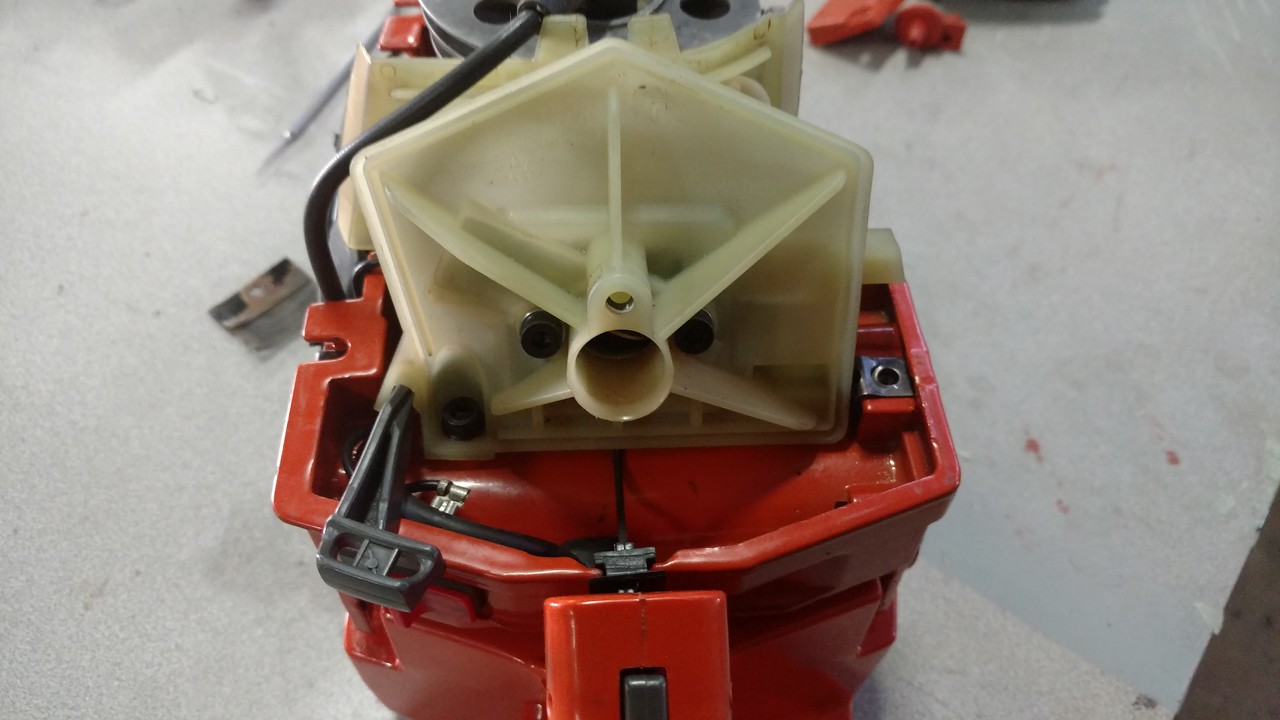

Spent the day at my favorite place @paragonbuilder shop and Dan helped me do my first complete assembly of the 51 rebuild project. Took a bunch of pics and I'm going to attempt to document everything here for you folks to enjoy.

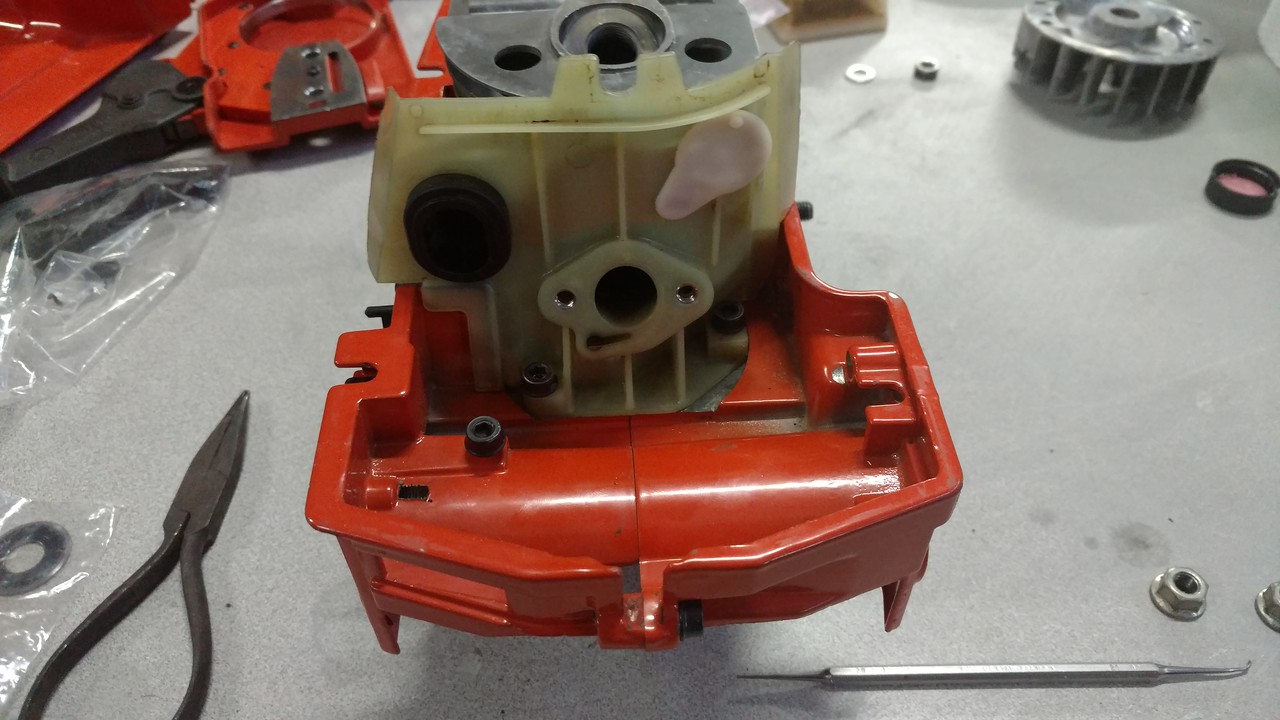

Started with a bench full of parts new and old. @Mattyo disassmbled this thing at Dan's GTG in minutes. I use purple power to clean the saw and organized all of the parts in a box. New parts include OEM bearings + seals, gasket kit, new 55 open port OEM piston/cylinder kit, clutch needle bearing, mesh air filter, fuel line, impulse tube grommet, probably a few other parts I forgot!

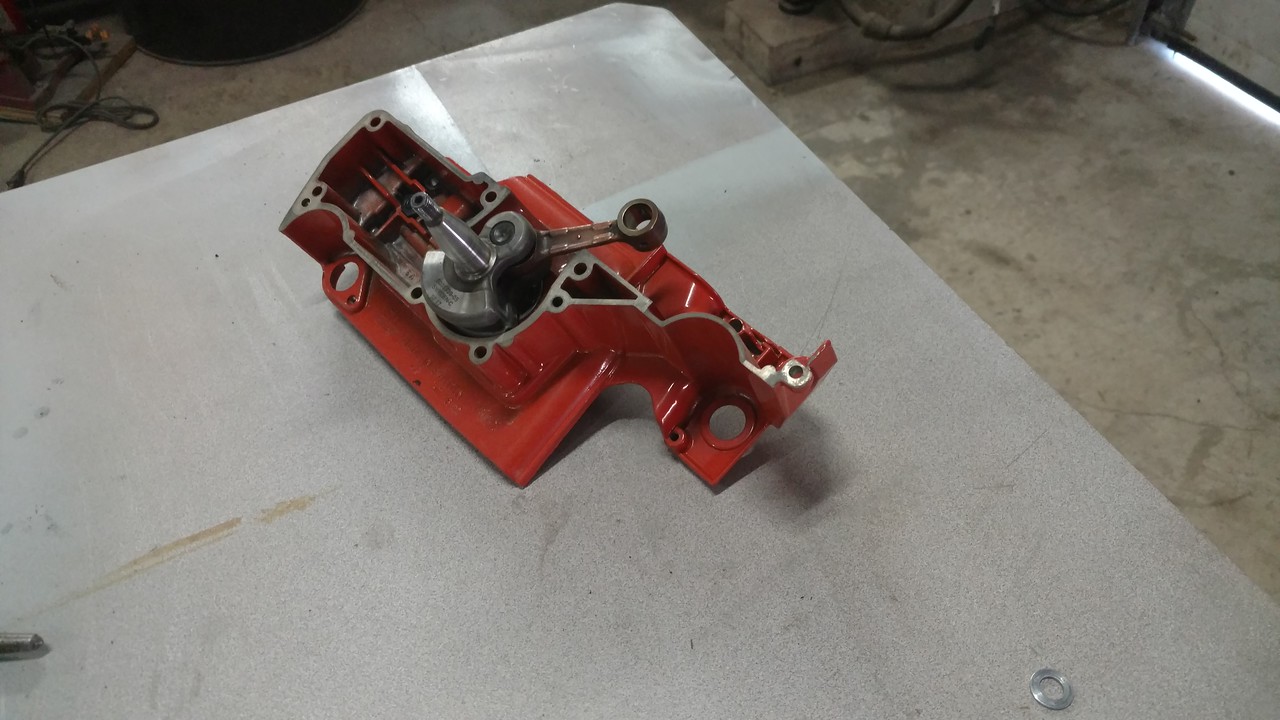

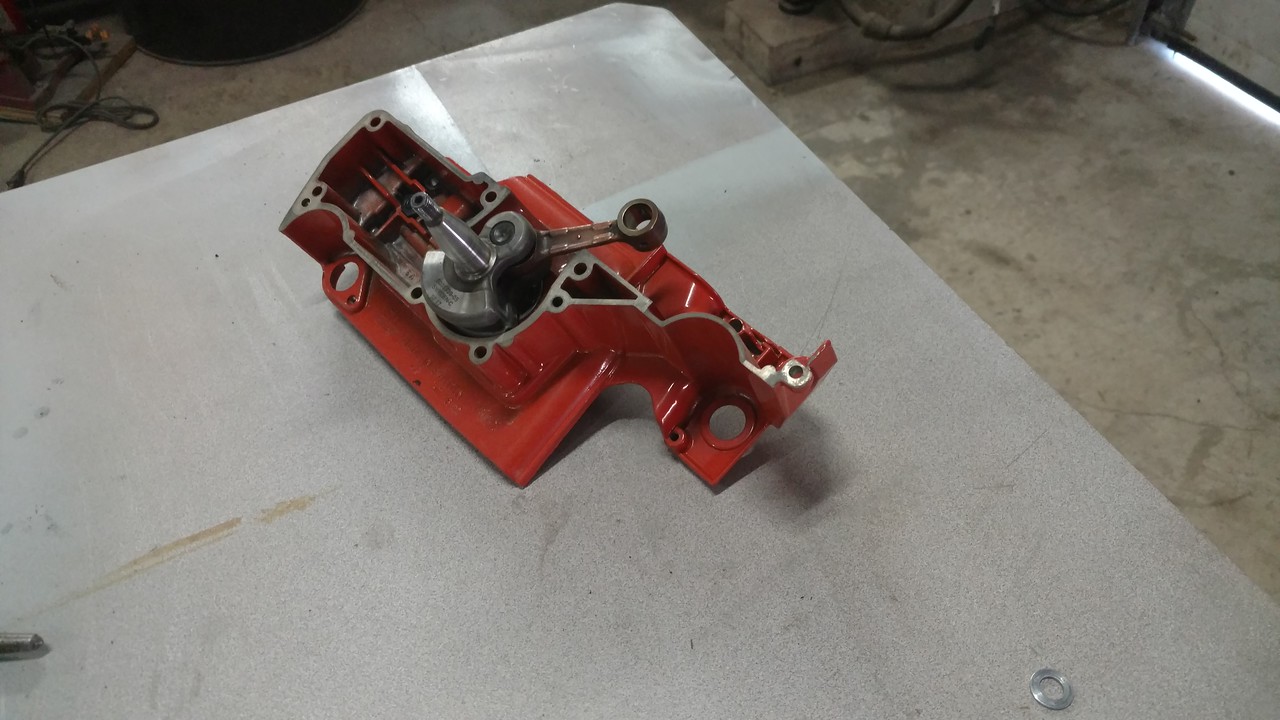

Dan's wood furnace was perfect for heating things up. First up case half to put first bearing in. Bearing put out on the snow no need for a freezer! First case half was well north of 350 degrees probably close to 500 but no problem.

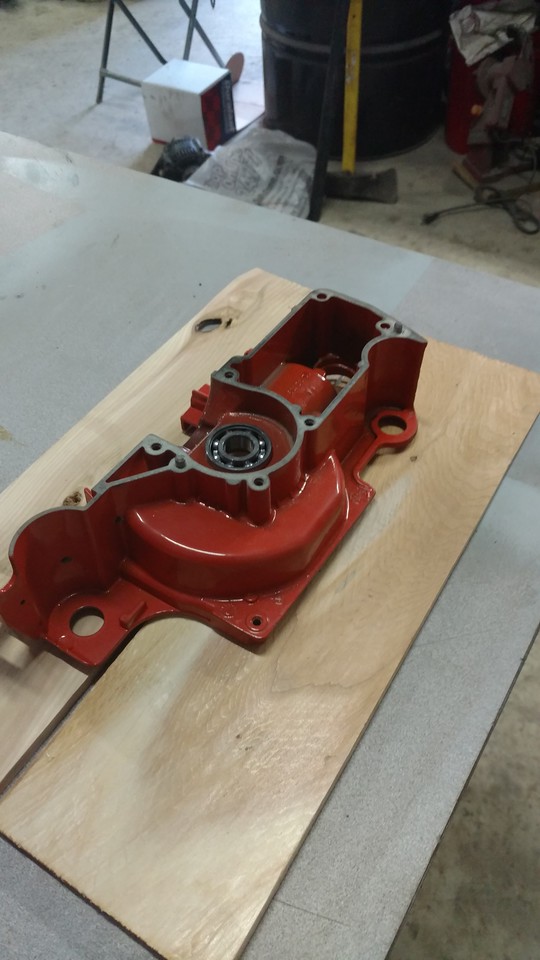

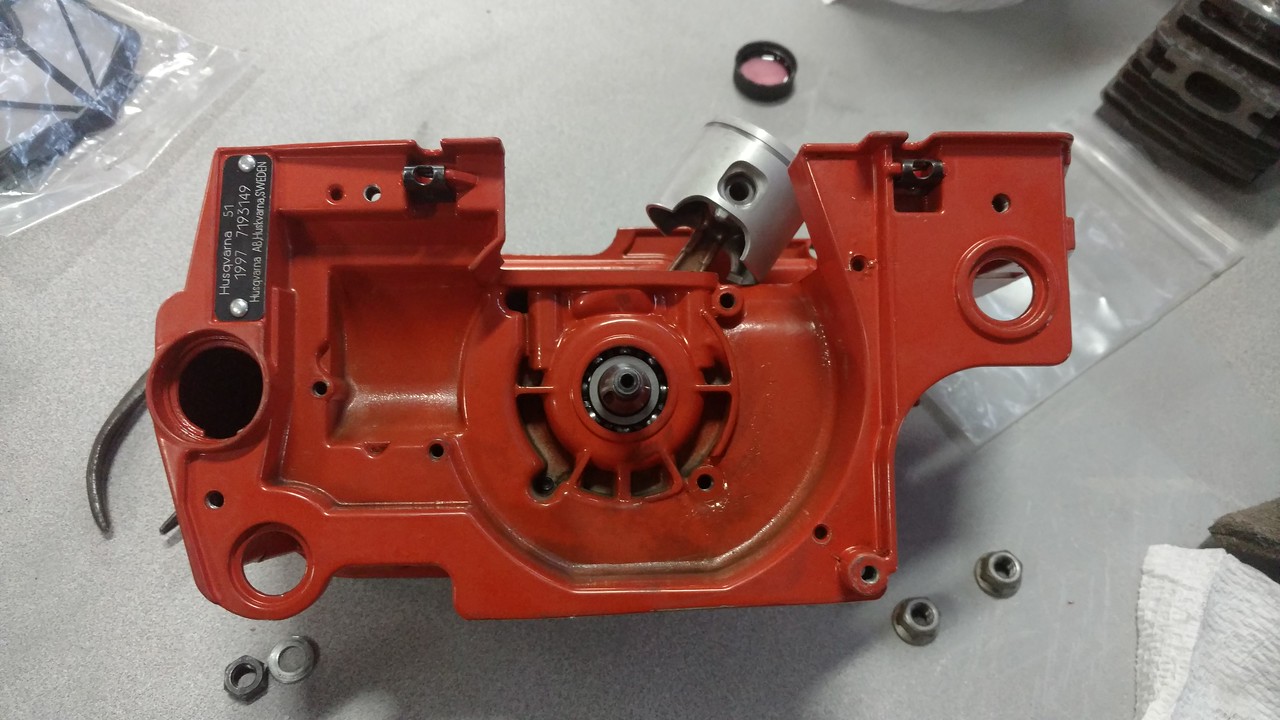

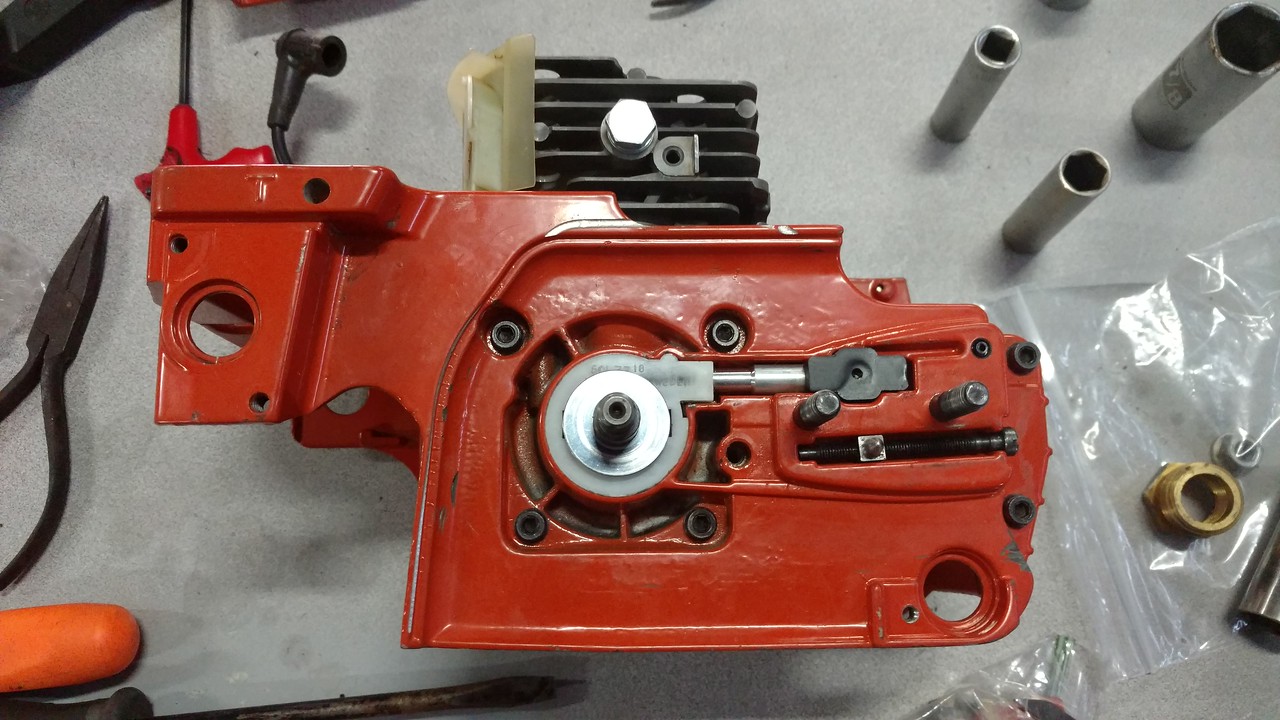

Bearing dropped in home in PTO side of case. No coaxing required at all!

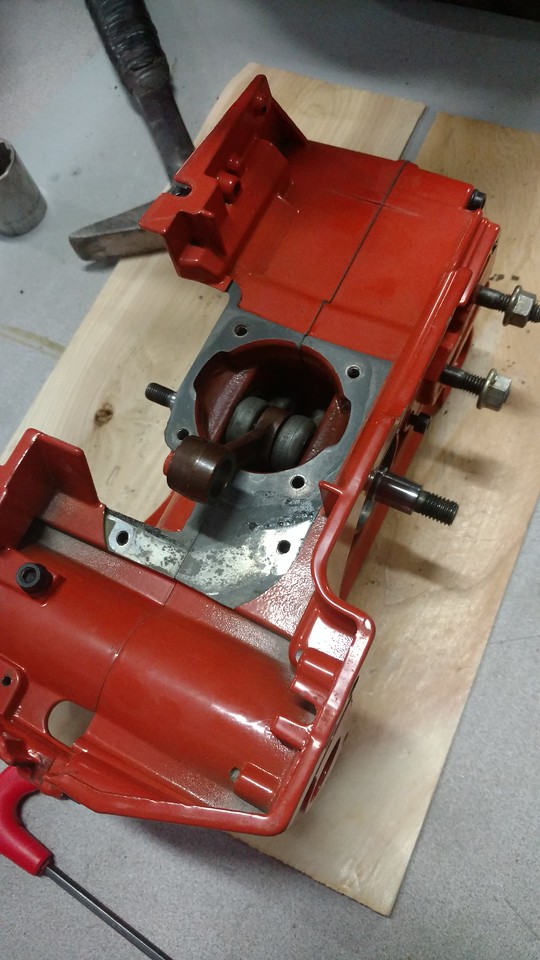

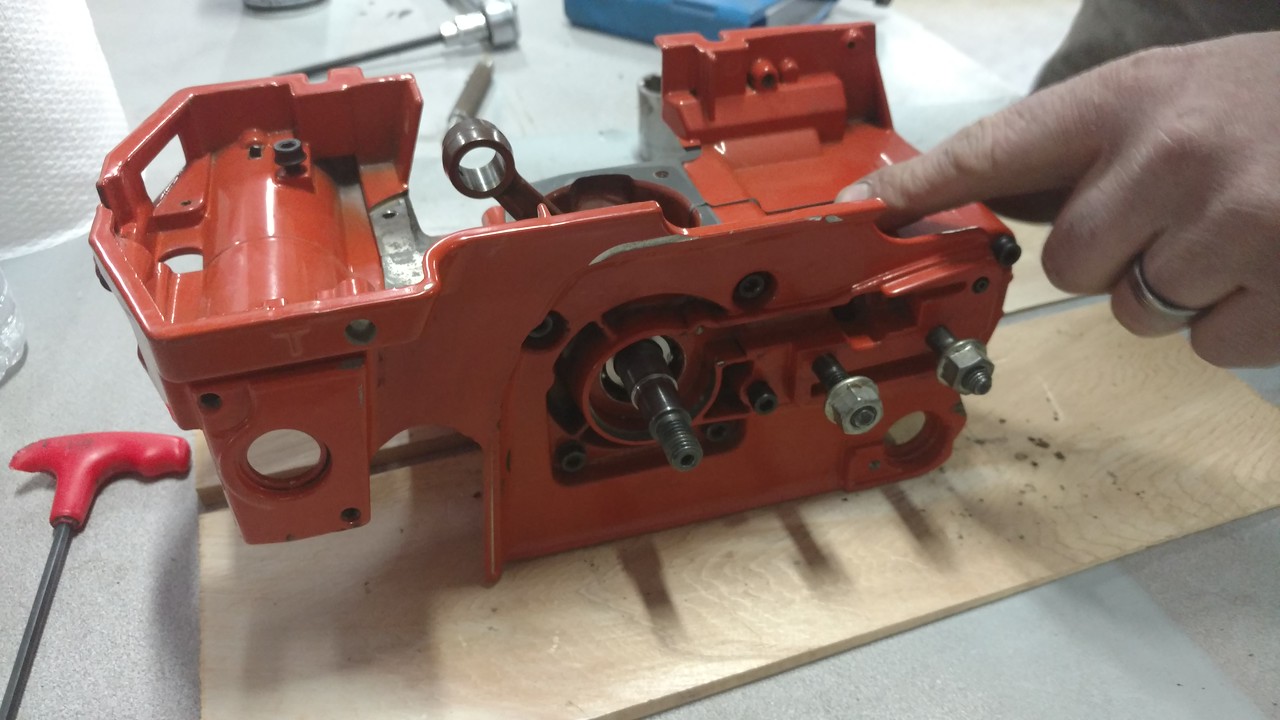

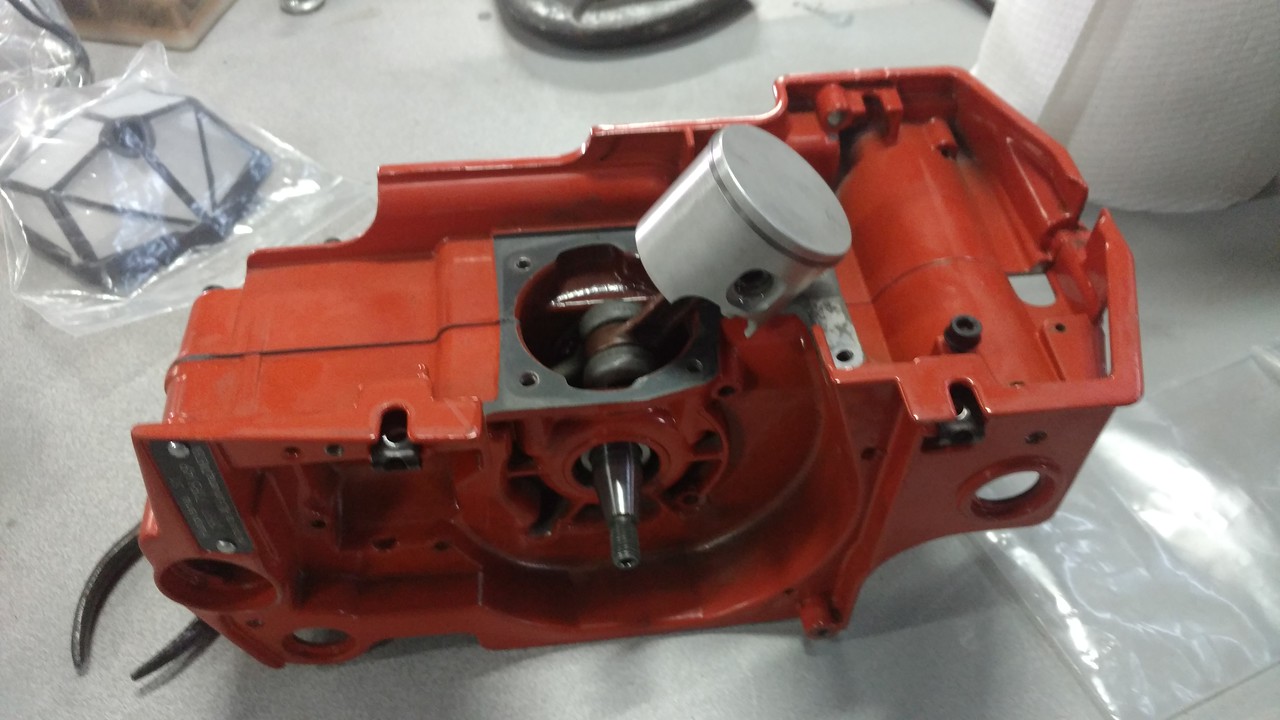

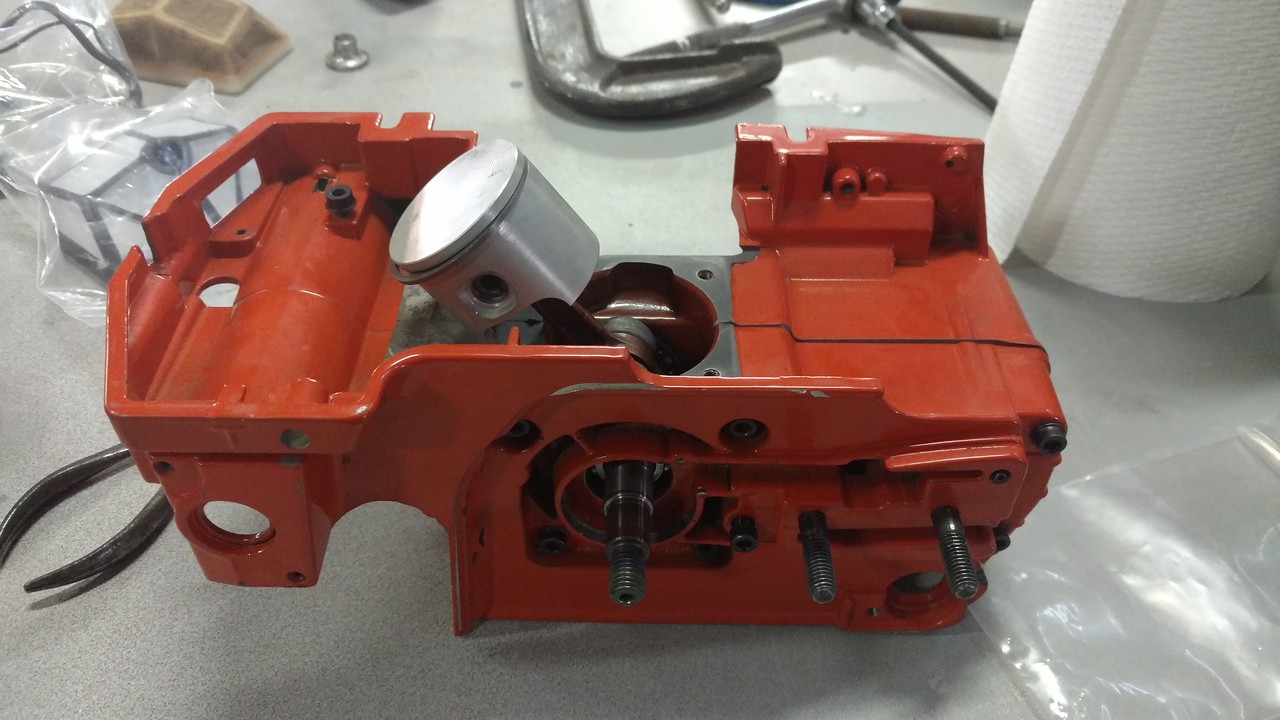

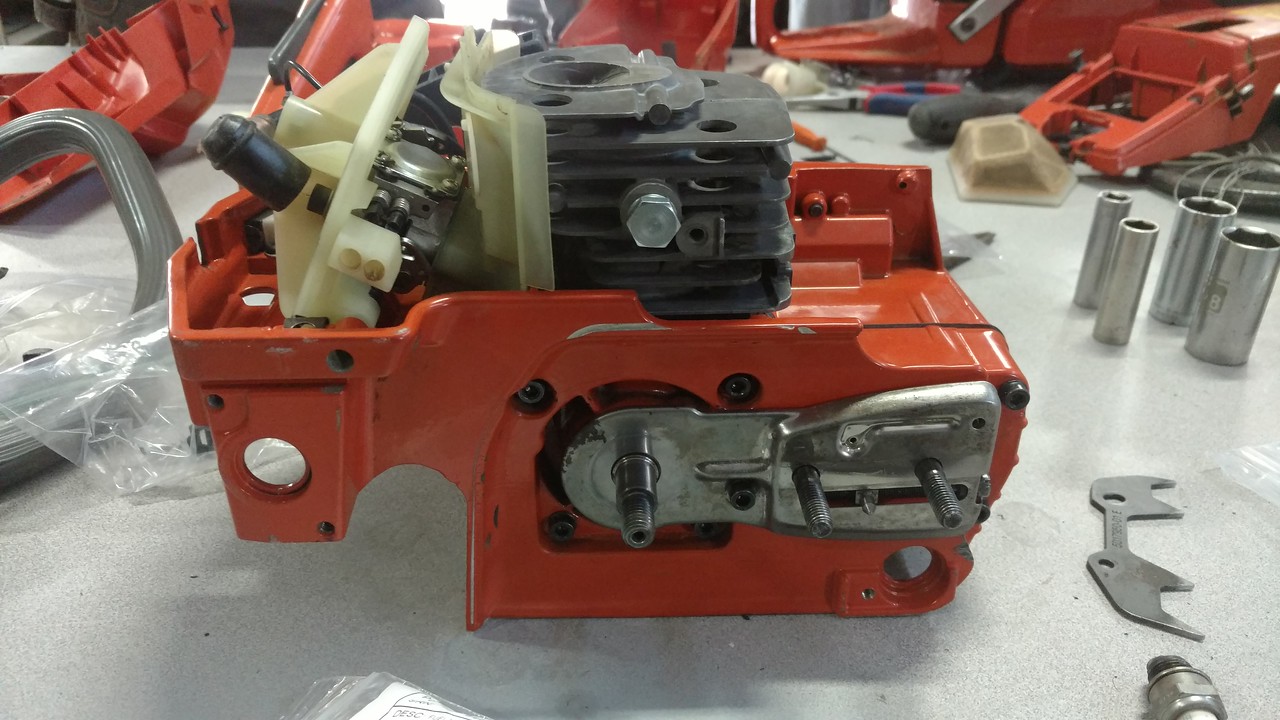

With a cold crank after some heat soaked into the PTO bearing we dropped the crank in. Used a center punch to save crank threads and a few taps to get the PTO side cam mostly where it belongs.

Flywheel side case half goes for bake in the furnace. Only takes about 10 mins to get up over 300 on the coals in there. More in next post.

Started with a bench full of parts new and old. @Mattyo disassmbled this thing at Dan's GTG in minutes. I use purple power to clean the saw and organized all of the parts in a box. New parts include OEM bearings + seals, gasket kit, new 55 open port OEM piston/cylinder kit, clutch needle bearing, mesh air filter, fuel line, impulse tube grommet, probably a few other parts I forgot!

Dan's wood furnace was perfect for heating things up. First up case half to put first bearing in. Bearing put out on the snow no need for a freezer! First case half was well north of 350 degrees probably close to 500 but no problem.

Bearing dropped in home in PTO side of case. No coaxing required at all!

With a cold crank after some heat soaked into the PTO bearing we dropped the crank in. Used a center punch to save crank threads and a few taps to get the PTO side cam mostly where it belongs.

Flywheel side case half goes for bake in the furnace. Only takes about 10 mins to get up over 300 on the coals in there. More in next post.