MustangMike

Mastermind Approved!

- Local time

- 3:06 PM

- User ID

- 338

- Joined

- Dec 30, 2015

- Messages

- 11,433

- Reaction score

- 35,921

- Location

- Brewster, NY

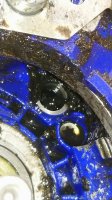

I just got to looking at the cylinder that came with my kit, and they didn't hone the upper 1/4" of the cylinder, and the plating has a hole flaked off up there too. Junk

If you need one of their cylinders, just let me know. I have only used Cross + OEM, I have several of them.

However, I think they make the 460 cylinders I have, and I have used 2 of them w/o any issues.

I think most of them will be OK with a Meteor piston, if you check all the bevels and make sure they are OK.