Wonkydonkey

Plastic member

- Local time

- 10:57 PM

- User ID

- 3189

- Joined

- May 14, 2017

- Messages

- 4,598

- Reaction score

- 18,380

- Location

- Sussex, UK.

well guys, I've had this generator for a few yrs, been used and abused. I got it secondhand It's a honda type gx160 engine. I will see if I can find a pic of it on the web. There's sure tobe one somewhere.

The problem I had/have. Is that it was low on power, I had to increase the engine revs to get 240vac even then. Some things like my table saw would not work.

Anyhow, after looking around. I found generator guru had the info that I needed to check the coils. It turned out to be the capacitor,

I looks around for one, I thinks I find one, but after waiting for it to arrive from China it was the wrong one. Pics can be deceiving of the size. So not being put off by this size thing, I set about wiring it up..

Well to my supprise. It worked, the generator was pumping out nearly 240v when the switch was on 110vac. I turned down the throttle screw. But I also had wired up my tacho, it was 2k and to get 110vac while the switch on to 110v I had to turn the revs down to 1500.

I then switched to 240v and got a steady 240v output..

While having the cover off where the capacitor would sit. And having the engine running. I noticed the bearing spinning and that it seemed to have some play in it.

I now had a bigger job on my hands.

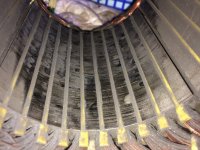

To take the end off the coil and look at the bearing meant I had pull the exhaust to get at the stator and rotor.

I did not have the time to continue this day so I had to find another time. So the next time was an whole afternoon put by for investgating

For those that don't know how the rotor is held on to the engine shaft, it is tapered. And a bolt pulls it on and it's held there.

To get it off you have to take this bolt out and then get a peice of threaded rod a little wider but also a little shorter, in the end of the rotor there's a thread for a bolt, get a bolt and thead it in, mark how much it goes in. Take it out, now your threaded rod needs to go in and be a little short so you can then get the bolt just threaded in the thread a few turns.

Now this is the worrying part. You have to start tight ing up the bolt in the end of the rotor which is pushing on the threaded rod but it's really pulling/pushing it off the tapered engine shaft.

I'll post some pics of what I found.

The problem I had/have. Is that it was low on power, I had to increase the engine revs to get 240vac even then. Some things like my table saw would not work.

Anyhow, after looking around. I found generator guru had the info that I needed to check the coils. It turned out to be the capacitor,

I looks around for one, I thinks I find one, but after waiting for it to arrive from China it was the wrong one. Pics can be deceiving of the size. So not being put off by this size thing, I set about wiring it up..

Well to my supprise. It worked, the generator was pumping out nearly 240v when the switch was on 110vac. I turned down the throttle screw. But I also had wired up my tacho, it was 2k and to get 110vac while the switch on to 110v I had to turn the revs down to 1500.

I then switched to 240v and got a steady 240v output..

While having the cover off where the capacitor would sit. And having the engine running. I noticed the bearing spinning and that it seemed to have some play in it.

I now had a bigger job on my hands.

To take the end off the coil and look at the bearing meant I had pull the exhaust to get at the stator and rotor.

I did not have the time to continue this day so I had to find another time. So the next time was an whole afternoon put by for investgating

For those that don't know how the rotor is held on to the engine shaft, it is tapered. And a bolt pulls it on and it's held there.

To get it off you have to take this bolt out and then get a peice of threaded rod a little wider but also a little shorter, in the end of the rotor there's a thread for a bolt, get a bolt and thead it in, mark how much it goes in. Take it out, now your threaded rod needs to go in and be a little short so you can then get the bolt just threaded in the thread a few turns.

Now this is the worrying part. You have to start tight ing up the bolt in the end of the rotor which is pushing on the threaded rod but it's really pulling/pushing it off the tapered engine shaft.

I'll post some pics of what I found.