You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Got a mates MS231 to mend

- Thread starter MattG

- Start date

angelo c

Coal Member

- Local time

- 10:53 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

Matt, I would swap out the bar/chain/sprocket in that order and see which one isolates that whirring. its in the driveline somewhere. seems to me ( from my armchair a few thousand kilometers away) that its binding somewhere as the chain seems to stop abruptly somewhat as well. Make sure the bar tip is free and not sliding in its bearing.

Cheers....as we say here in the lovely "New" Jersey.

Cheers....as we say here in the lovely "New" Jersey.

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

Thanks for all your ideas and help people,

What @angelo c said about something nipping up around the PTO side is quite astute. Yeah I did notice that although the chain doesn't creep along with the clutch, it (the chain) did stop very quickly after a cut.

But what @Adamski and @huskyboy said about the f/w side is worth a check.

I'll take a good look today and see what else I find.

Still wish these tree guys would be more descriptive about what they actually want checking on their saws!!!

What @angelo c said about something nipping up around the PTO side is quite astute. Yeah I did notice that although the chain doesn't creep along with the clutch, it (the chain) did stop very quickly after a cut.

But what @Adamski and @huskyboy said about the f/w side is worth a check.

I'll take a good look today and see what else I find.

Still wish these tree guys would be more descriptive about what they actually want checking on their saws!!!

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

So I spent a bit of the morning re-looking at it. Basically the noise was Bar and chain related. I think since I'm used to MMd and ported out saws of late, and this saw is newish (well 2011  and EPAd, I just heard the noise more...

and EPAd, I just heard the noise more...

This is it with no B/C

this is with my 14" setup, chain tensioned how I usually do

and back to the customers 16" setup tensioned as loose as I dare:

I did later set Darren's saw up in the vice and I reckon the chain has a lot of tight spots, various points where it'd snag by several mill (5-6 I think) and others where it jumps back into the bar.

Also found some slight burrs on inside of the outer edge of the cl. drum, but I just dressed these before greasing the bearing and reassembling.

This is it with no B/C

this is with my 14" setup, chain tensioned how I usually do

and back to the customers 16" setup tensioned as loose as I dare:

I did later set Darren's saw up in the vice and I reckon the chain has a lot of tight spots, various points where it'd snag by several mill (5-6 I think) and others where it jumps back into the bar.

Also found some slight burrs on inside of the outer edge of the cl. drum, but I just dressed these before greasing the bearing and reassembling.

angelo c

Coal Member

- Local time

- 10:53 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

So I spent a bit of the morning re-looking at it. Basically the noise was Bar and chain related. I think since I'm used to MMd and ported out saws of late, and this saw is newish (well 2011and EPAd, I just heard the noise more...

Ok ooooh....do I get a prize ?

Like a like a few 200t handle replacements or maybe a 036 oiler line redo?

This is it with no B/C

this is with my 14" setup, chain tensioned how I usually do

and back to the customers 16" setup tensioned as loose as I dare:

I did later set Darren's saw up in the vice and I reckon the chain has a lot of tight spots, various points where it'd snag by several mill (5-6 I think) and others where it jumps back into the bar.

Also found some slight burrs on inside of the outer edge of the cl. drum, but I just dressed these before greasing the bearing and reassembling.

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

angelo c

Coal Member

- Local time

- 10:53 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

I got the derned kits....its the skills to use them I'm lacking!!!

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

Anyway the saw seems like it has recently been serviced. (So being a suspicious guy I still suspect that I was being given an "honesty test" ?? Opinions please !).

The plug looks clean and a couple months old, gap is spot on. The A/filter was very clean. It oils and revs so well that I'll didn't bother with the gas and oil filters - I'm sure they will be fine, but if he wants to pay for more work from me, then I'll certainly change out.

I can still faintly see machining (from the factory) marks on the piston so it's ran well, and has been maintained properly.

there is slight coloration below the ring land, but I imagine this to be normal as the exhaust side of a 2 stroke will probably char left over skirt oil over time.

man but aren't these stratos weird??? This is the first one I've looked at through the muffler, and you can see weird coloration again on the cylinder wall:

however I know that things are ok ish with it, due to the visibility of the factory's circumferential lines on the piston body, and when I was (just about) able to squint through the tiny plug hole:

I see a very clean piston crown.

The plug looks clean and a couple months old, gap is spot on. The A/filter was very clean. It oils and revs so well that I'll didn't bother with the gas and oil filters - I'm sure they will be fine, but if he wants to pay for more work from me, then I'll certainly change out.

I can still faintly see machining (from the factory) marks on the piston so it's ran well, and has been maintained properly.

there is slight coloration below the ring land, but I imagine this to be normal as the exhaust side of a 2 stroke will probably char left over skirt oil over time.

man but aren't these stratos weird??? This is the first one I've looked at through the muffler, and you can see weird coloration again on the cylinder wall:

however I know that things are ok ish with it, due to the visibility of the factory's circumferential lines on the piston body, and when I was (just about) able to squint through the tiny plug hole:

I see a very clean piston crown.

angelo c

Coal Member

- Local time

- 10:53 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

Matt. Can you check the compression on that saw. Trying to think through the build-up below the bottom ring. Looks like some combustion is getting past the rings

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

I wish I could Ange , thing is, it's got one of those tiny NGK CMR6H plugs. Too small for my tester, I guess I need an adapterMatt. Can you check the compression on that saw. Trying to think through the build-up below the bottom ring. Looks like some combustion is getting past the rings

The comp feels ok on a pull, but it's only ~41cc saw, so who knows? Certainly looks ok and piston wear (i.e. lack of) dept.

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

Update on this saw. The owner ended up asking me to muffler mod the saw. I opened the outlet, hacked at the inner baffle as much as I could reach to do so, and as there seemed to be a lot of metal overlapping the gasket at the flange + the muffler inlet, I carefully dremeled this away. Then I removed the stupid limiter cap on the H screw and (eventually!) watched Brad's tuning a rev-limited saw for clues on what to do.

Here's what it's currently like:

Insults and comments welcome.

Here's what it's currently like:

Insults and comments welcome.

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

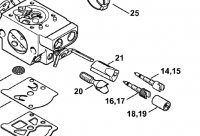

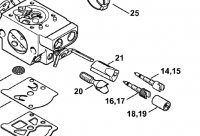

Ok, this is where I'm asking for advice and opinions. So I took off the limiter cap that was one the H screw. Yes only one fitted to this model just for the H side.

So I'm wondering whether I should reinstall another cap, but with the locking lug removed, in order to help hold the screw in position? However I think that as the L screw which of almost identical design has no such cap fitted, then the H screw will be ok just leaving as it is. I hope so, since I'm kinda starting to get bored with working on this particular saw...

So I'm wondering whether I should reinstall another cap, but with the locking lug removed, in order to help hold the screw in position? However I think that as the L screw which of almost identical design has no such cap fitted, then the H screw will be ok just leaving as it is. I hope so, since I'm kinda starting to get bored with working on this particular saw...

angelo c

Coal Member

- Local time

- 10:53 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

Ok, this is where I'm asking for advice and opinions. So I took off the limiter cap that was one the H screw. Yes only one fitted to this model just for the H side.

View attachment 107662

So I'm wondering whether I should reinstall another cap, but with the locking lug removed, in order to help hold the screw in position? However I think that as the L screw which of almost identical design has no such cap fitted, then the H screw will be ok just leaving as it is. I hope so, since I'm kinda starting to get bored with working on this particular saw...

its easier to find the hole( fat chick rolling in flour ect) when you leave the cap fitted but trimmed off to allow full range of motion.

the screw driver tends to wonder about less with the cap...

MattG

Chainosaurus Rex

- Local time

- 3:53 PM

- User ID

- 3111

- Joined

- Apr 30, 2017

- Messages

- 896

- Reaction score

- 1,432

- Location

- Cambridgeshire, England

I know what you are saying Ange, it was a right PITA, until I managed to find the *exact* screwdriver, and marked on it's shank where this slipped down to against the cover, such that the flat of the driver was in the chick's slot (continuing your analogy I believe).its easier to find the hole( fat chick rolling in flour ect) when you leave the cap fitted but trimmed off to allow full range of motion.

the screw driver tends to wonder about less with the cap...

But do you reckon I'm good leaving the cap off seeing as the L doesn't even come with one? Just getting kind of sick of working on that saw......thought I do think she sounds and runs a lot better after my MM

angelo c

Coal Member

- Local time

- 10:53 AM

- User ID

- 362

- Joined

- Dec 31, 2015

- Messages

- 2,919

- Reaction score

- 11,552

- Location

- Peoples Republic of North Jersey

Pure preference...but when the saw is bouncing around on a stump and I'm trying to tune it with one hand and hold it with the other...I know what you are saying Ange, it was a right PITA, until I managed to find the *exact* screwdriver, and marked on it's shank where this slipped down to against the cover, such that the flat of the driver was in the chick's slot (continuing your analogy I believe).

But do you reckon I'm good leaving the cap off seeing as the L doesn't even come with one? Just getting kind of sick of working on that saw......thought I do think she sounds and runs a lot better after my MM

The less I fiddle with ....and the more I screw....the better...

I've done both ways and settled with cutting tabs and returning. These new style limited tend to suck though.

Similar threads

- Replies

- 15

- Views

- 290

- Replies

- 595

- Views

- 53K