fin460

Super OPE Member

- Local time

- 4:50 AM

- User ID

- 314

- Joined

- Dec 29, 2015

- Messages

- 131

- Reaction score

- 366

- Location

- NW Missouri

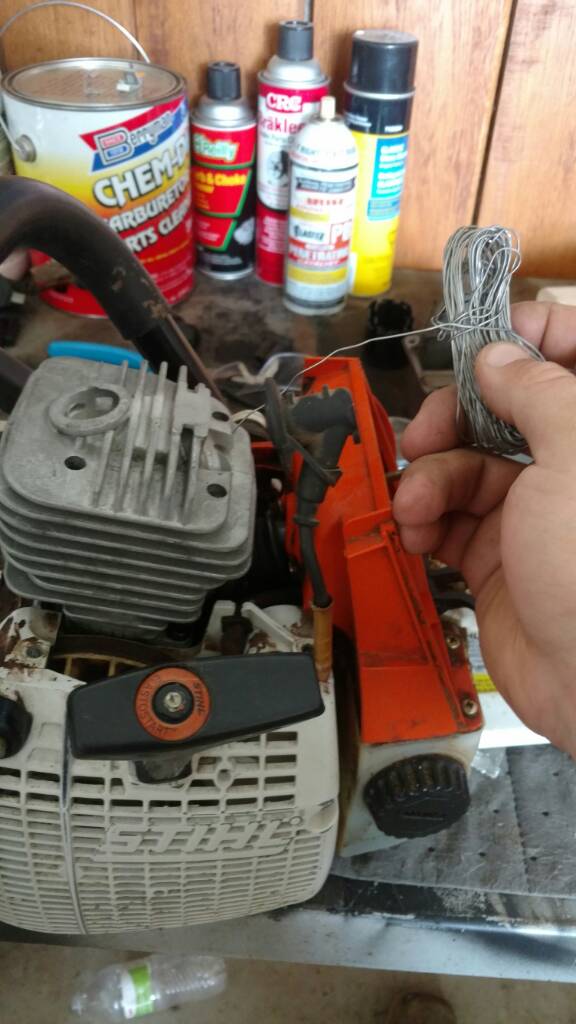

Randy @Mastermind sent me a prototype Cross Performance 066 top end this spring on the condition I do a build thread for it. I'm slow and I'm in the process of installing it now on a nice ms660 for a neighbor that he bought this spring with a blown top end.