Philbert

Chainsaw Enthusiast

- Local time

- 9:03 PM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 4,434

- Reaction score

- 17,906

- Location

- East Dakota

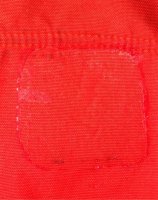

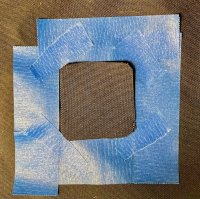

The protective fibers of chainsaw chaps are inside: cuts or burns to the outer shell only are mostly cosmetic, but should be repaired to keep out dirt, sawdust, oil, etc., and to prevent further damage. If the fibers have been pulled by a chain strike, the chaps have done their job and should be retired.

The USFS has published some information on this, but it is pretty old, and pertains to their, specific chaps. E.g. STIHL brand chaps are machine washable - check the labels on yours to be sure.

Inspecting and Repairing Your Chain Saw Chaps - USFS

https://www.fs.fed.us/t-d/pubs/pdfpubs/pdf05672816/pdf05672816dpi72.pdf

Inspecting, Cleaning, Repairing, and Retiring USDA Forest Service Chain Saw Chaps (0451–2324–MTDC)

https://www.fs.fed.us/t-d/pubs/htmlpubs/htm04512324/

Philbert

The USFS has published some information on this, but it is pretty old, and pertains to their, specific chaps. E.g. STIHL brand chaps are machine washable - check the labels on yours to be sure.

Inspecting and Repairing Your Chain Saw Chaps - USFS

https://www.fs.fed.us/t-d/pubs/pdfpubs/pdf05672816/pdf05672816dpi72.pdf

Inspecting, Cleaning, Repairing, and Retiring USDA Forest Service Chain Saw Chaps (0451–2324–MTDC)

https://www.fs.fed.us/t-d/pubs/htmlpubs/htm04512324/

Philbert