Just getting together some things to start milling hardwoods for the most part. Lots of saw questions.

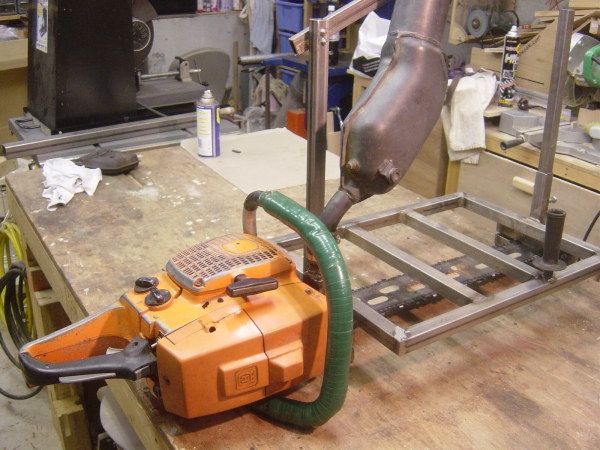

I will be using Stihl saws from 60cc-90's for now. Might need to go bigger, might not. Might need to buy another brand.

The cons:

DON'T want. old *s-word like 075 or 2100's

1. No parts support.

2. Saws with upright filling caps.

3. Saws that tend to run hot.

4. Short strokes and big bores tend not to fair well under a huge constant load, avoiding them for the most part.

5. Saws with horrible AV and ignition problems.

6. Chainsaw milling is hard on everything saw related I'm told.

The pros:

1. Relatively cheap quality parts cause I'll be spending my money on saw consumables and go go juices.

2. Side fill caps are a MUST! for me.

3. Cold blooded overgrown pigs of a saw don't matter much here.

4. Long strokes and big clutches will help.

5. Saws with decent AV and no known ignition problems.

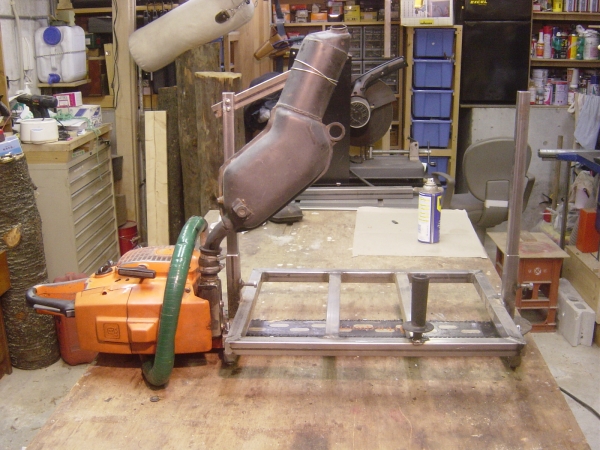

6. A saw can have a tuned pipe and appropriate port work, mods, ect...

7. The longer bar(s) won't matter with a good acc oiler.

8. Saws will be set up for rough and finish work.

*9. None of this matters on the beaming saw. Yes one will be dedicated to just that.

10. All fine finish resawn will be sent out or a band brought in.

11. Doing beams, posts and lumber for myself to use!

12. I'd rather not do dry wood for now. Green sawn and gone is the plan.

13. A yoke and winch seems to be the best way to pull a chainsaw mill vs pushing it.

So, here we go with the 660, 394/5, you need a 9000 bla bla bla...

Tell me why your saw is so great at milling and what could be better.

It would be nice to here from guys in the field actually milling logs or have done so in the past and not with all the fancy smancy new high-tech expensive stuff and stuffs. Always interested in others set ups for work related activity. I'm not trying to reinvent the wheel here.