Jimmy in NC

Pinnacle OPE Member

- Local time

- 1:22 AM

- User ID

- 57

- Joined

- Dec 23, 2015

- Messages

- 1,994

- Reaction score

- 8,010

- Location

- North Carolina

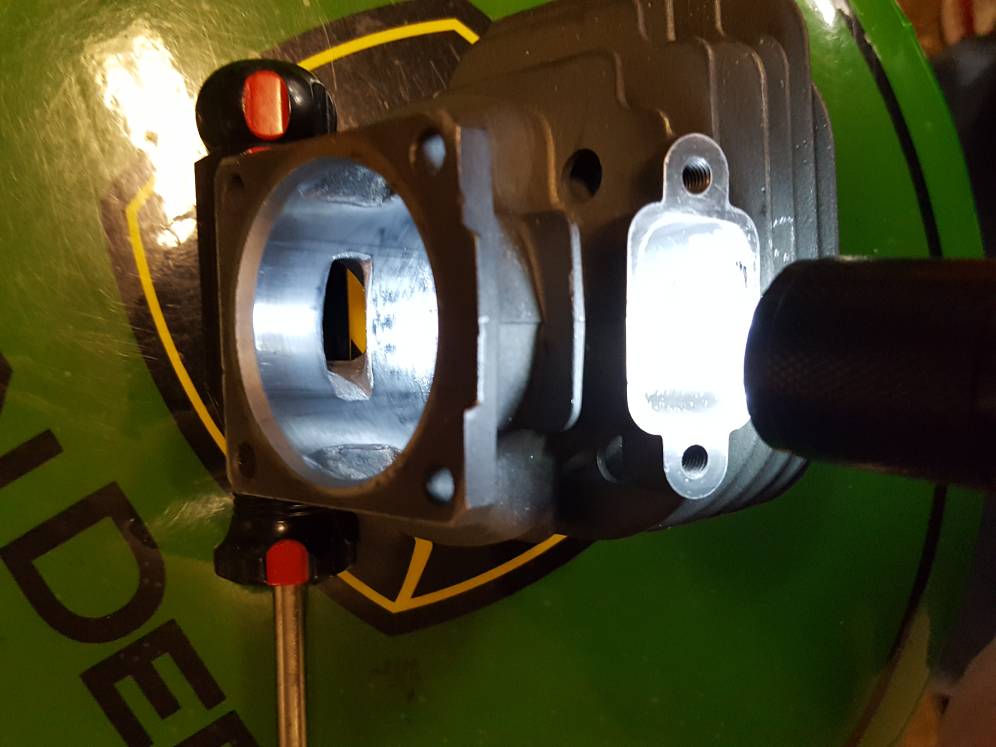

Okay...

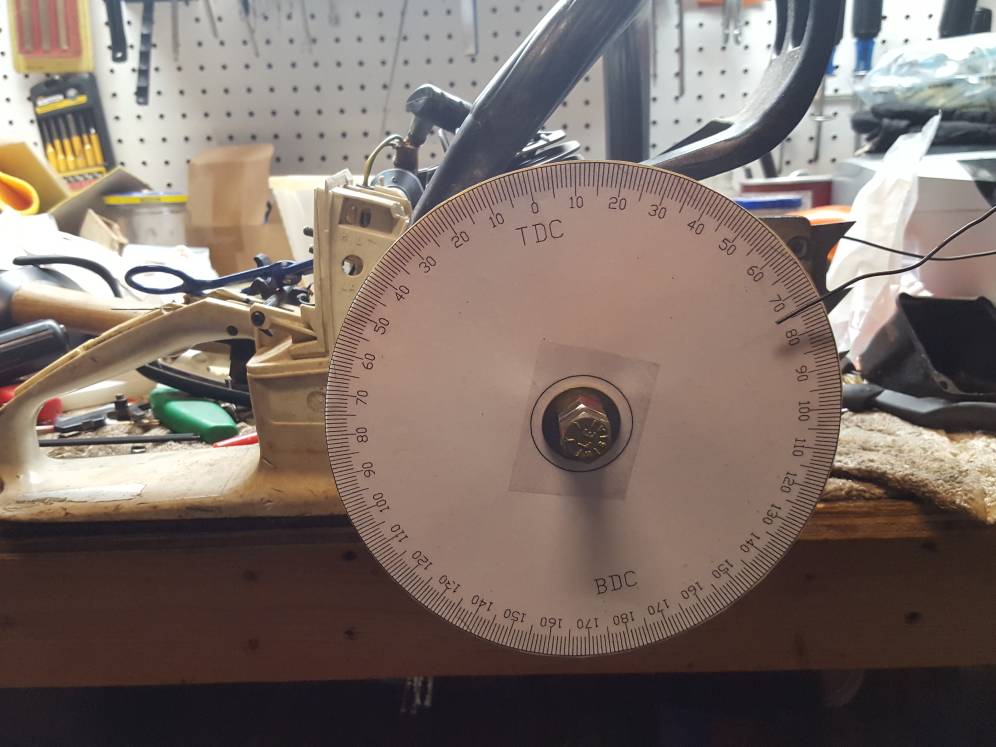

I setup the wheel and got actual port opening numbers on the AM jug. I know most like duration numbers but my mathing isn't going real well right now.

TDC - 0°

Exhaust - 98°

Transfers - 120°

Intake - 73.5°

So with my head clearing and my stomach holding food... can someone tell me if I have the durations correct? Trying to learn the whole process here.

Intake - 147°

Transfers - 120°

Exhaust - 164°