Rich Fife

Sally slap my ass

- Local time

- 1:26 AM

- User ID

- 26245

- Joined

- Mar 4, 2023

- Messages

- 708

- Reaction score

- 1,065

- Location

- Central New York

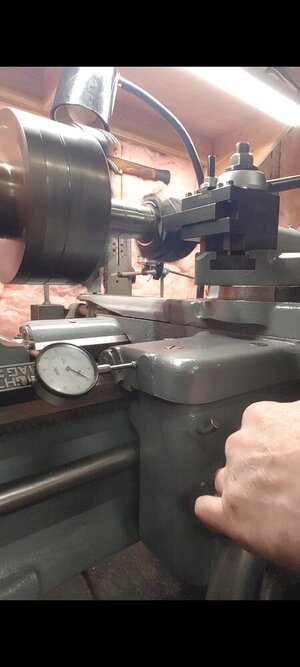

A buddy asked me If I would work over his buddies saw... I said sure... tell him to cover the parts I put into it and we will be good. When I picked up this saw, it was Filthy... and it had a resident, a BIG spider turned the Exhaust into a home...

Attachments

Last edited: