- Local time

- 7:59 PM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 8,935

- Reaction score

- 62,235

- Location

- Coastal Oregon

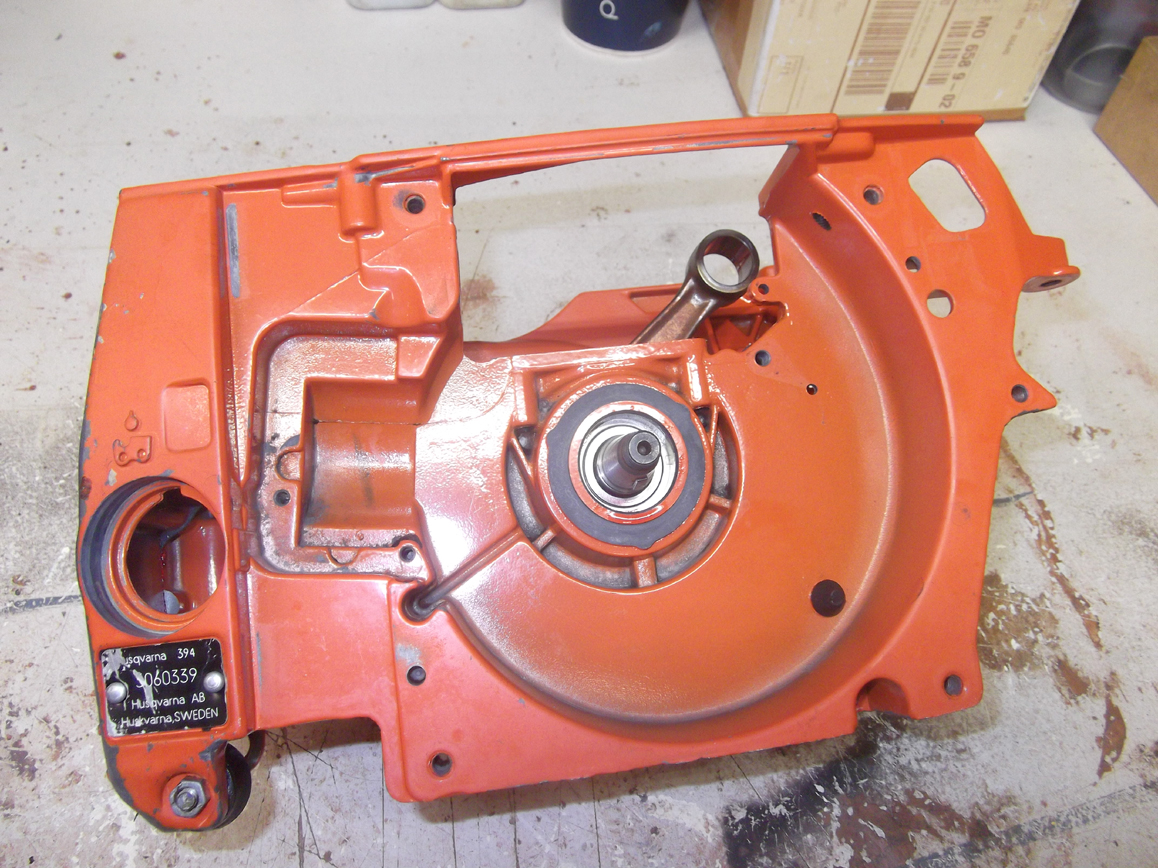

I thought you guys might like to go through another HVA 394 build-em-up. A member here had a crisis moment a few weeks ago and was looking for some help with projects - I thought I'd volunteer my time and some parts and get this old boy back on the road.

The saw came from the son of a legendary builder who passed away several years ago. It looks like it was started but never finished. The cylinder has had some porting, but I'll need to get an idea of what kind of numbers it has in it before I know if it's going to be a real runner.

The owner didn't want me to split the case on it, but I'm glad I did. The PTO side of the case had some damage and after coming apart, I found that the PTO side main bearing has a broken cage. I thought about re-using his old case gasket, but decided it had given its all.

The owner only gave me two instructions: "Nuttin' fancy" and "No dead kittens in the crankcase."

The saw came from the son of a legendary builder who passed away several years ago. It looks like it was started but never finished. The cylinder has had some porting, but I'll need to get an idea of what kind of numbers it has in it before I know if it's going to be a real runner.

The owner didn't want me to split the case on it, but I'm glad I did. The PTO side of the case had some damage and after coming apart, I found that the PTO side main bearing has a broken cage. I thought about re-using his old case gasket, but decided it had given its all.

The owner only gave me two instructions: "Nuttin' fancy" and "No dead kittens in the crankcase."

Last edited: